- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

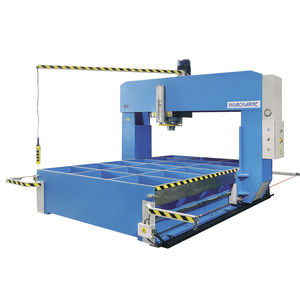

Manual press LRD-500 Ehydraulicpunchingstraightening

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic, manual

- Function

- bending, straightening, deep drawing, punching, welding

- Structure

- downstroke, with floating headstock

- Control

- semi-automatic

- Applications

- process, for sheet metal

- Force

500 tf

- Opening

350 mm

(14 in)- Stroke

350 mm

(13.78 in)- Table width

2,800 mm

(110 in)- Table length

1,200 mm

(47 in)- Working speed

2 mm/s

- Return speed

12 mm/s

- Approaching speed

7 mm/s

Description

As all our L series hydraulic presses, is designed with a moveable head to perform work involving fretwork, deep-drawing, punching, bending, straightening, etc.

STRUCTURE AND TABLES

Consist of an electro welded structure made solely of ST-52.3 steel.

They are stabilised and machined at the end of the structural welding process to ensure perfect parallelism and precision.

Calculated and designed by finite software with level 5 structural resistance.

Upper of 2800 x 1200 mm made with CK-42 stainless steel table with two T DIN-650 grooves.

CYLINDER AND HYDRAULIC UNIT

The cylinder is double acting of stroke of 350 mm and 500 tons with a lapping liner, chrome plunger and maintenance-free anti wear guides.

Motorized sliding headstock of 2000 mm.

Vertical useful light 450 mm.

A two-speed motorized hydraulic unit of 11 kw with automatic high speed deactivation.

Its equipped with a cylinder decompression valve.

Approaching speed 7 mm/s. working speed 1.5 mm/s and return speed 12 mm/s.

ELECTRIC INSTALLATION AND SAFETY

The control panel features a switch enabling the user to select the desired type of work in a manual or semi-automatic position and a switch to select either the fast approach speed or slow operational speed.

Operation is carried out by means of a pendant control station with an emergency stop and low-voltage operation. It includes an operation confirmation button.

It meets and satisfies all the essential health and safety requirements in accordance with the EC standard.

Catalogs

No catalogs are available for this product.

See all of HIDROGARNE‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.