Power ultrasound is well known for its intense and precisely controllable milling and dispersing effects. Industrial ultrasonicators provide a highly uniform particle size distribution in the micron- and nano-range. Industrial ultrasonicators process easily large volume streams of high viscosities and fulfill a homogeneous wetting, dispersing, deagglomeration and milling.

Paint Manufacturing with Ultrasound

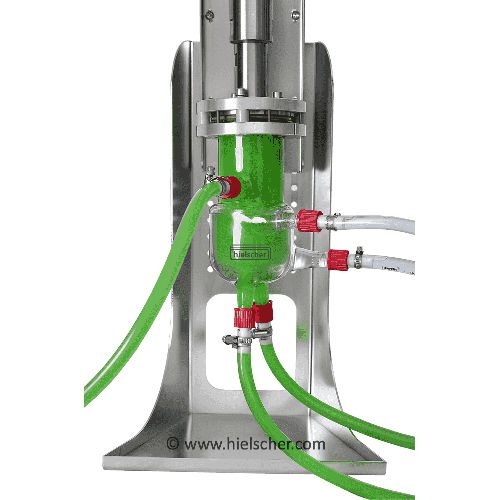

Improve your Paints, Colors and Coatings with Sonication: Formulation: Whether high viscosities, high particle loads, aqueous- or solvent-based – with Hielscher’s industrial inline ultrasonicators you can process any formulation. Micron- and Nano-Size: The cavitational high shear forces reduce particles to minute particle diameters and provide an uniform dispersion.

High-Performance Particles: Smaller particle sizes result in greater colour saturation, colour consistency and stability. The intense, yet precisely controllable ultrasound forces allow for producing modified and functionalized nano-particles, such as coated particles, SWNTs, MWCNTs and core-shell particles. Such particles show unique characteristics and elevate paint or coating formulations to a new level of quality and functionality (e.g. UV resistance, scratch resistance, strength, adhesiveness, high heat resistance, infrared and solar reflectivity). Modified Particles: Surface modified pigments have very low viscosity at high pigment loadings (2.5cP at 10% solids), superior suspension stability and high purity