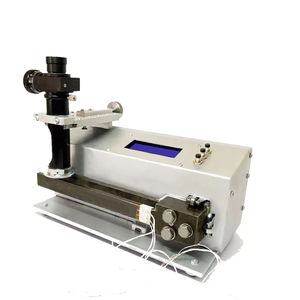

- Industrial machines and equipment

- Furnace and Heat Treatments

- Chamber oven

- High precision measurement LLC

Chamber furnace TRCF-0500-*heat treatmentholdingelectric

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- heat treatment, holding

- Heat source

- electric

- Other characteristics

- automatic

- Maximum temperature

Max.: 500 °C

(932 °F)Min.: 0 °C

(32 °F)- Width

600 mm

(23.62 in)- Height

600 mm

(23.62 in)- Depth

600 mm

(23.62 in)

Description

The furnace has a temperature controller to regulate the temperature in the furnace chamber in accordance with the heat treatment programs for various adhesives and cements used in strain measurement of parts and assemblies.

The use of preset programs ensures that the entire heat treatment cycle is carried out in automatic mode and eliminates possible errors associated with incorrectly setting the temperature and/or the time of temperature set-up or holding on the “shelf” by the user, and also frees the user from the need to reconfigure the controller to proceed to the next heat treatment step.

A set of programs (up to 20 programs) is set during the manufacture of the furnace in accordance with the needs of the Customer.

In addition, there is a “Manual” mode, in which the user can independently set an arbitrary heat treatment program containing from 1 to 3 steps, for each step the following is set: temperature, temperature rise time and holding time at a given temperature.

Additionally, the furnace, when executing the program, registers the values of the actual and calculated temperature in accordance with the heat treatment program being executed with a period of 1 to 5 minutes, which makes it possible to check the correctness of the choice and execution of the program after the end of the heat treatment.

Catalogs

No catalogs are available for this product.

See all of High precision measurement LLC‘s catalogsOther High precision measurement LLC products

Special equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.