- Industrial machines and equipment

- Furnace and Heat Treatments

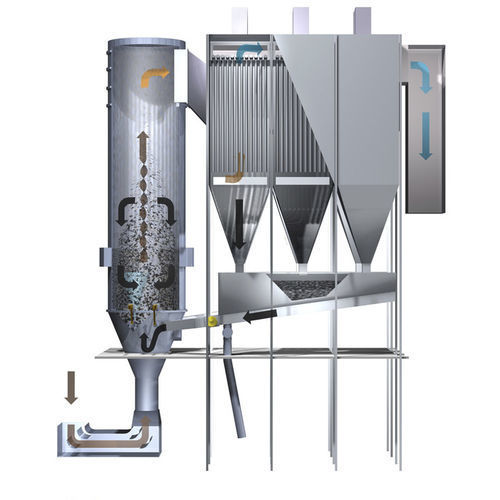

- Fluidized bed dryer

- Hitachi Zosen Inova AG

Fluidized bed dryer SemiDrycontinuous

Add to favorites

Compare this product

Characteristics

- Technology

- fluidized bed

- Batch/continuous

- continuous

Description

The HZI SemiDry system involves a semi-dry sorption process employing the principle of the circulating fluidised bed.

Hydrated lime is injected into the fluidised bed reactor to neutralise corrosive acid gases. The temperature in the reactor is key to the sorption process. To achieve the ideal reaction temperature (typically 145°C), water is sprayed into the reactor simultaneously. In addition to regulating the temperature, the water reactivates the recirculated residues, optimising the separation efficiency of the process.

Low emissions and high efficiency if there are changes in the concentration of pollutants in the flue gas (high buffer capacity to prevent spikes resulting from the large quantity of solids in the system)

Low sensitivity to fluctuations in temperature on entering the reactor (temperature regulated by injection of water)

High energy efficiency compared with lime slurry-based systems

High availability and low operating and maintenance costs thanks to use of proven equipment with only a small number of mechanical components

With a stand-alone SemiDry system, the upper BREF limits can be achieved.

By retrofitting a DC scrubber, the low BREF values can also be achieved – thanks to the combination with the SemiDry, still wastewater-free

Catalogs

Semi-Dry System

2 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.