- Products

- Catalogs

- News & Trends

- Exhibitions

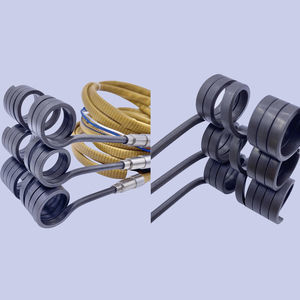

Insulated band heater standardceramicmica

Add to favorites

Compare this product

Characteristics

- Protection level

- insulated, standard

- Other characteristics

- ceramic, mica

Description

Here you can find kinds of band heaters for different applications. Nozzle band heaters for the nozzles of injection molding machines. Mineral insulated band heaters at high temperatures with high voltages. Mica band heaters for plastic extruders, injection and blow molding machines.

Nozzle Band Heaters are primarily used at plastic injection molding machinery in the polymer processing industry. They are further suitable for Hot Runner system, for transferring tubes with bitumen processing, for bag sealers and for special purpose machinery manufacture.

Optional built in thermocouple type J for direct control the nozzle heater

Heater band materials: brass, stainless steel, aluminum.

Operating temperature: max. 600 celsius degrees.

Available in standard design, but can also be fully customized.

Ceramic Band Heaters are primarily used in all common machinery of the injection moldings, extruders, pipeworks and circular containers.

Afford customers a means to heat large cylinders from intermediate to high temperatures of 1600°F (870°C) without concern of failures.

Offers a well-balanced heat transfer into the next layer of metal and comes with a clamping screw and spring; this feature makes the installation easy.

The ceramic band heaters can be manufactured with different dimensions, clamping mechanisms, terminations styles, holes and cut-outs.

Mica band heater is an internal mounted band heater, used for pipe heating, plastics injection molding, extrusion, blow molding applications.

The construction of a mica band heater is done with high quality resistance wire, micanite sheets and a high temperature treated stainless steel casing.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.