- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

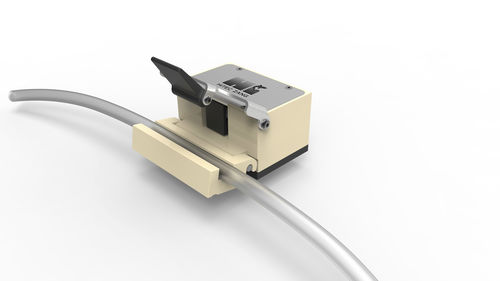

Absolute pressure sensor IS-P-TUBE-INLAY seriesdifferential4-20 mAM12 connector

Add to favorites

Compare this product

Characteristics

- Pressure type

- absolute, differential

- Output

- 4-20 mA

- Electrical connection

- M12 connector

- Material

- stainless steel, aluminum

- Protection level

- IP65

- Process temperature

Min.: 10 °C

(50 °F)Max.: 50 °C

(122 °F)

Description

These innovative pressure sensors measure the pressure or the differential pressure on normal hoses from the outside. They are therefore above all suited for sterile applications. No components need to be fitted in the hose, the system is completely sterilised and the hose is simply placed into the sensor after sterilisation. The innovative measuring principle is legally protected.

The sensor can in particular be used for pressure measurement and filter monitoring in biotechnical, sterile systems.

Due to the measuring principle the specification is greatly dependent on the hose characteristics (diameter, wall thickness, material). The values given below must therefore only be regarded as being approximate. Major deviations may occur In particular for thin hoses and large wall thicknesses. In practice, significantly better specifications will generally be achieved with careful calibration for hose diameters from 10 mm.

• Suitable for sterile uses

• Media compatibility determined by hose material

• Can be mounted at a later date

• Differential or absolute pressure can be measured

• Measuring principle : Measurement of the wall force from outside (non-invasive)

• Resolution : < 1 mbar

• Characteristic curve deviation* : ≤ 50 mbar

• Zero point stability : ≤ 30 mbar

• Reproducibility* : ≤ 20 mbar

• Hysteresis error* : ≤ 30 mbar

• Stability/year* : ≤ 50 mbar

• Setting time (10...90 %)* : approx. 1 sec

Catalogs

No catalogs are available for this product.

See all of HiTec Zang GmbH‘s catalogsRelated Searches

- Pressure probe

- Analog pressure probe

- Relative pressure probe

- Stainless steel pressure probe

- Absolute pressure sensor

- Waterproof pressure sensor

- Digital pressure sensor

- Compact pressure probe

- DC pressure sensor

- Differential pressure sensor

- IP65 pressure sensor

- Flush diaphragm pressure sensor

- M12 connector pressure sensor

- Aluminum pressure sensor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.