- Hydraulics - Pneumatics

- Pump

- Gear pump

- HNP Mikrosysteme GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

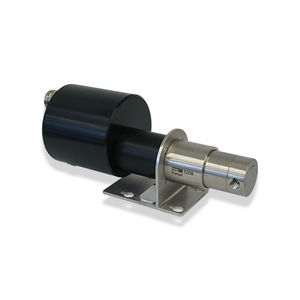

Dosing pump mzr-2905gearpaintfor solvents

Add to favorites

Compare this product

Characteristics

- Technology

- gear

- Fluid

- paint, for solvents, for coolant, for adhesives, for resin, for crude oil, for ink, polymer, oil

- Operation

- with DC motor

- Priming

- self-priming

- Mobility

- stationary

- Domain

- industrial, for the pharmaceutical industry, for the metallurgical industry, for the automotive industry, for the printing industry, medical, for machine tools, for the steel industry, for renewable energy

- Applications

- for industrial applications, process, for centralized lubrication systems, high-pressure, dosing, filling, for machinery, for lubrication units, high-precision, lubrication, suction, for printing machines, mobile, micro-dispensing, for vehicles, for automatic machines, for low-pressure applications, for lubrication systems

- Material

- stainless steel, metal, hard metal

- Fluid specification

- for low-viscosity fluids, for medium-viscosity products, for high-viscosity fluids, for mineral oil, dye, for fluids with lubricating properties, for refrigerant fluids, flavouring

- Voltage

- 24 V

- Protection level

- abrasion-resistant

- Other characteristics

- high-performance, compact, high-efficiency, small, for fluids, micro, servo-driven, high-power, small-size, programmable, integrated-drive, micro-flow, low-capacity, with integrated controller

- Flow

Min.: 0 l/min

(0 us gal/min)Max.: 0.018 l/min

(0.00476 us gal/min)- Pressure

Min.: 0 bar

(0 psi)Max.: 30 bar

(435.113 psi)- Power

44 W

(0.06 hp)- Fluid temperature

Min.: -5 °C

(23 °F)Max.: 150 °C

(302 °F)- Input diameter

28 mm

(1.102 in)- Output diameter

28 mm

(1.102 in)- Length

140 mm

(6 in)- Width

45 mm

(1.77 in)- Height

65 mm

(2.56 in)- Weight

790 g

(27.87 oz)

Description

For industrial production and process technology

The micro annular gear pump mzr-2905 covers the flow rate range 0.003-18 ml/min. To the main assets of the device belong high precision, low pulsation, low volume dosage even of non-lubricating liquids or at high pressures, compact design and an integrated microcontroller. The pump allows dosage in a broad viscosity range and shows small, economic dimensions. The mzr-2905 targets applications in industrial production and process technology. The pump has been designed for continuous delivery and discrete dosage of water, watery solutions, solvents, methanol, oil, lubricants, adhesives, inks and paints as well as other high viscosity liquids.

Advantages

High dosage precision precision CV < 1 % at low volumes

High differential pressures achievable also for low viscosity liquids

Compact dimensions length 140 mm, including controller

Broad viscosity range methanol, water, solvents, adhesives, grease, gel

Low pulsation delivery, low shear stress rotary micro annular gear technology

Long service life wear-resistant tungsten carbide

Precision motor and sophisticated control DC-servomotor with integrated microcontroller

Application

Chemical processing

Industrial and plant engineering

Packaging

Medical and pharmaceutical industry

Mini plant technology

Spray technology

Dispensing of adhesives

Ink and paint dosage

Vacuum applications

Catalogs

No catalogs are available for this product.

See all of HNP Mikrosysteme GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other HNP Mikrosysteme GmbH products

High performance pump series

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.