- Metrology - Laboratory

- Optical Component

- Zero order waveplate

- Hobbite.Co., LTD

Zero order waveplate true

Add to favorites

Compare this product

Characteristics

- Options

- zero order, true

Description

The true zero order waveplate is designed to highly accurate application. Its thickness is very thin(less than 0.1mm) which make the true zero order waveplate excellent in temperature,wavelength and incident angle bandwidth.

To suit different applications,our true zero order wave plates are classified into Cemented true zero order waveplate by Epoxy,Single plate true zero order waveplates,Telecom true zero order waveplate.

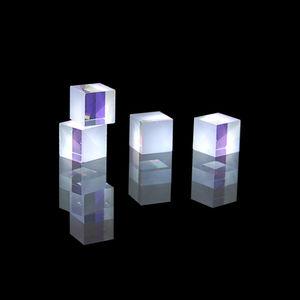

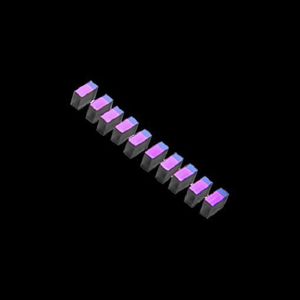

True Zero Order Waveplates- Single Plate

This type of zero order waveplate is designed for high damage threshold applocation (more than 1GW/cm2). As the plate is very thin, it’s easy to break during operation.

•Single Plate

•Wide Angle Acceptance

•Better Temperature Bandwidth

•Wide Wavelength Bandwidth

•High Damage Threshold

•Thin Thickness:0.04~0.09 microns

•AR Coated, R<0.2%

Standard Wavelength Applied:

/4: 1480nm,1550nm

/2: 980nm,1064nm,1310nm,1480nm,1550nm

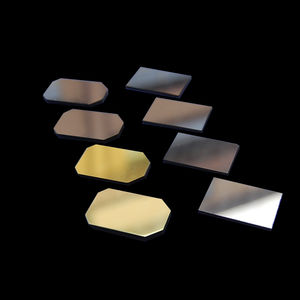

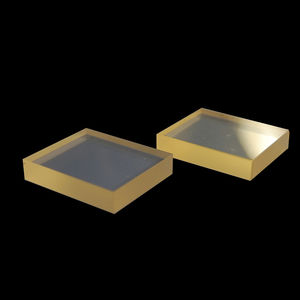

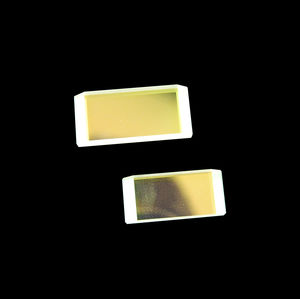

True Zero order Waveplate- Cemented

This type of zero order waveplate is constructed of a true zero order waveplate and a BK7 substrate.As the waveplate is very thin and easy to be damaged,the Bk7 plate’s function is to strengthen the waveplate.

•Cemented by Epoxy / Optical contact

•Wide Angle Acceptance

•Better Temperature Bandwidth

•Wide Wavelength Bandwidth

•AR Coated, R<0.2%

Standard Wavelength Applied:

/4: 532 nm,632.8nm,780nm,808nm,850nm,980nm,1064nm,1310nm,1480nm,1550nm

/2: 532 nm, 632.8nm,780nm,808nm,850nm,980nm,1064nm,1310nm,1480nm,1550nm

Catalogs

No catalogs are available for this product.

See all of Hobbite.Co., LTD‘s catalogsRelated Searches

- Glass lens element

- Optical prism

- Spectrum lens element

- Optical lens element

- Glass optical prism

- Visible lens element

- BK7 lens element

- Laser lens element

- Silica lens element

- Glass mirror

- Fused silica lens element

- Laser mirror

- BK7 optical prism

- Beamsplitter

- Optical glass lens element

- Anti-reflective lens element

- Polarizer

- Fused silica optical prism

- Right-angle optical prism

- Aspherical lens element

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.