- Industrial machines and equipment

- Mixing and Dosing

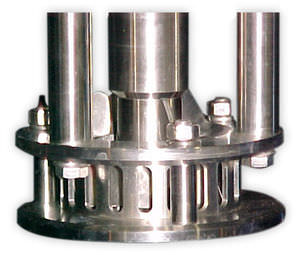

- High-shear disperser

- Hockmeyer Equipment Corporation

- Products

- Catalogs

- News & Trends

- Exhibitions

High-shear disperser batchhigh-speedfluid

Add to favorites

Compare this product

Characteristics

- Type

- high-shear

- Batch/continuous

- batch

- Other characteristics

- high-speed

- Applications

- fluid

Description

A Disperser is a single shaft mixer used to break apart or dissolve solid particles in a liquid. This is typically accomplished using a "saw tooth" blade rotating at high speed (approximately 5200 feet per minute peripheral speed). The blade imparts high shear forces to the ingredients being dispersed, breaking them apart. Through proper blade selection and sizing, a flow can be established that will repeatedly turn over the batch and yield a homogeneous product. Dispersers are most often used to mix low viscosity products such as paints.

Dispersers are available with variable speed mixing shafts. Some are directly mounted atop a tank and are fixed to operate with the blade in only the original mounting position. Other tank mounted dispersers can raise and lower the blade by several feet (to better control the vortex) without exiting the tank. Another design, perhaps the most popular, places the disperser on top of a hydraulic lift that is mounted to the floor. The lift enables the operator to raise the blade completely out of the mixing vessel and change to another vessel. This technique uses small portable tanks (up to 500 gallons) that can be rolled away on wheels or picked up with a fork truck. Larger stationary tanks are often centered within the arc of rotation from the center of the hoist to the center of the mixing shaft. The bridge containing the mixing shaft at one end and the motor at the other is then rotated from one tank to the next. Choosing the best configuration of available designs is a combination of functional need and economic justification.

Catalogs

No catalogs are available for this product.

See all of Hockmeyer Equipment Corporation‘s catalogsOther Hockmeyer Equipment Corporation products

Dispersers & Agitators

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Grinding mill

- Liquid agitator

- Vertical agitator

- Horizontal grinding mill

- Rotor lump breaker

- Paddle blender

- Turbine agitator

- Building materials grinding mill

- Disperser homogenizer

- Disperser

- Helical agitator

- Ore grinding mill

- Batch disperser

- High-speed disperser

- Fluid disperser

- High-shear disperser

- Multi-axis mixer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.