- Products

- Catalogs

- News & Trends

- Exhibitions

Drum dosing feeder Omnidosesemi-automaticfor medical devicesfor pharmaceutical products

Add to favorites

Compare this product

Characteristics

- Type

- drum

- Operating mode

- semi-automatic

- Product applications

- powder, for pharmaceutical products, for medical devices

- Other characteristics

- compact

Description

The Omnidose meets all product development requirements in galenics, allowing the semi-automatic production of small batches and clinical trial samples. With various dosing principles, all forms of powder can be optimally dosed. Barrier technology even allows highly effective and toxic products to be processed.

Benefits

• Optimum dosing system for each product

• Safe processing of highly effective and toxic product with powder containment

• Scaling to production standard thanks to standardized processes

• Easy operation and maintenance

• Can be used in a variety of applications

Technical data

• Dosing volume: approx. 20 mm³ – approx. 1000 mm³

• Dosing range: 10 – 5000 mg*

• Particle size: 1 µm and higher

* At a reference density of the powder of 0.5 mg per mm³

Final products

• Capsules

• Devices

• Blisters and discs

• Powder reservoirs

• Vials

• Cartridges

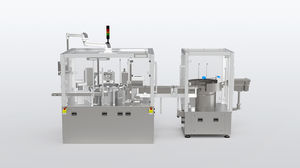

Machine features

Filling capsules

Various systems for capsule filling allow the dosing of powders, pellets, tablets, mini tablets, powder blends, active ingredients or liquids. It is even possible to dose capsules into capsules.

Filling blisters

The powder filling module can be equipped with a drum filler or with a membrane filler. The drum filler produces partially filled cavities whereas membrane filler is filling the blister cavity to 100%.

Trolley concept

The patented dosing trolley system allows the operator to quickly change the dosing method: Whether powder, pellets, tablets, mini tablets or liquid – the next dosing process is already set up. Short setup times, fast cleaning, maximum productivity. Plug-and-play options for the process change.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.