- Products

- Catalogs

- News & Trends

- Exhibitions

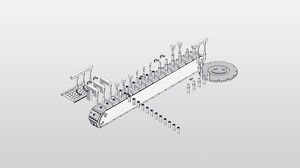

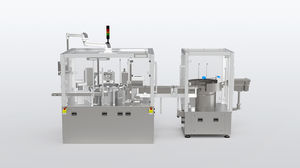

Drum dosing feeder Omnidose Extendeddiscsemi-automaticpowder

Add to favorites

Compare this product

Characteristics

- Type

- drum, disc

- Operating mode

- semi-automatic

- Product applications

- powder

- Other characteristics

- laboratory

Description

The Omnidose Extended is based on the proven powder dosing machine Omnidose. During the machine design phase it can be flexibly completed with further processes such as blister forming, heat sealing or additional assembly steps. The output of the semi-automatic laboratory machine is ideal for various development stages, and its scalable processes create a solid basis for subsequent production.

Benefits

• Automatic product transport between the individual stations by rack drive

• The basic equipment consists of freely selectable modules and can be set up individually

• Suited for a variety of packaging requirements

• Easy scaling from small series to production scale

Technical data

• Dosing volume: approx. 1mm³ – approx. 1,000 mm³

• Dosing range: 0.5 - 500 mg*

• Particle size: from 1 µm

* With a reference powder density of 0.5 mg per mm³

Final products

• Capsules

• Devices

• Discs

• Multi-chamber products

• Vials

• Blisters

• Powder reservoirs

• Cartridges

Machine features

Micro-dosing

Various dosing methods allows the dosing of minimal quantities of powder. Depending on the individual powder properties different filling methods such as membrane filling, tamping pin, dosator or drum filling are applicable.

Filling blisters

The powder filling module can be equipped with a drum filler or with a membrane filler. The drum filler produces partially filled cavities whereas membrane filler is filling the blister cavity to 100%.

Filling discs

Preformed cavities are positioned in the product working fixture. Minimum quantities of powder are filled using a membrane filling method with synchronously working fill positions.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.