- Products

- Catalogs

- News & Trends

- Exhibitions

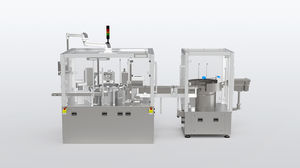

Automated filling machine Modu-C seriescapsuleliquidspowder

Add to favorites

Compare this product

Characteristics

- Operational mode

- automated

- Container type

- capsule

- Product applications

- liquids, powder

- Domain

- for the pharmaceutical industry

- Other characteristics

- flexible, cleaning

- Throughput

25,000 p/h, 100,000 p/h, 200,000 p/h

Description

The Modu-C MS Containment is especially designed for safe and flexible capsule production for which increased operator protection is necessary, such as for OEB class 4 (1-10 μg/m³). Even in the containment variant, the patented trolley system allows a rapid change of dosing systems. The machine is impressive with its easy operation and minimal setup and downtimes during format changes and cleaning.

Benefits

• Flexibly expandable with the patented dosing trolley system

• PRP function (person reduced production) Calibration bar to detect deformed capsules, exhaust function of deformed capsules, differential pressure measurement to inspect the presence of capsule bottoms, capsule closure inspection and single elimination of bad capsules

• 100% control units to ensure operator protection and adherence to the necessary filling requirements (temperature, humidity, negative pressure, etc.)

• Minimum product loss with no-cap-no-fill function

• Supported by Pharma Services

• User-friendly pre- and post cleaning and minimal setup times

Technical data

• Formats: All common capsule sizes

• Dosing units: Roller, pipette, tamping station, pellet, table, mini-tablet and liquid

Periphery

• Empty capsule feed in containment design

• Customer-specific product feeding in containment design

• In-line and online weight determination: Static gross/net inspection, 100% gross/net inspection, 100% net inspection via capacitive AMV sensor for minimal quantities dosing

• Capsule dedusting

• Metal detector

Final products

• Capsule production for combination and single dosages

VIDEO

Related Searches

- Packing machine

- Automatic filler

- Automatic packing machine

- Bagging machine

- Liquid filler

- Automatic labelling machine

- FFS bagging machine

- Semi-automatic filler

- Film packing machine

- Bell type packing machine

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Labeller for the pharmaceutical industry

- Case packer

- Medical packing machine

- Checkweigher

- Automatic case packer

- Bag filler

- Packaging machine for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.