- Products

- Catalogs

- News & Trends

- Exhibitions

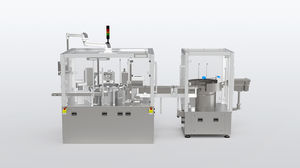

Automatic filling and sealing machine LOTbagbottlefor tubes

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Container type

- bag, bottle, for tubes, container

- Fill product

- liquids

- Product applications

- for pharmaceutical products, for medical devices

Description

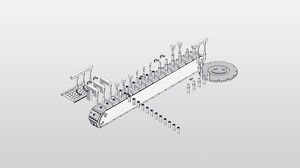

Numerous processes can be integrated on the oval motion machine platform. In addition to device assembly with separate parts and the integrated inspection processes, the platform satisfies precise dosing tasks – especially for drug delivery devices or inhalers. The compact design makes it possible to easily apply various barrier concepts.

Benefits

• Aseptic, pharmaceutical GMP design; modular setup with a choice of different stations

• Integrated film handling, punching and sealing

• Labeling, marking and printing, including inspection system

• Welding and hemming processes using thermal, laser and ultrasonic technology

• Inspection processes such as leak tightness and flow inspections, plus pressure, force, weight and torque measurements up to overall functions testing

• Fully automatic processing of different devices Machine features

Technical data

• Output: up to 60 cycles/min

• Stations: 12-50

• Exception: 1 to 8 grooves

• Clean room design option: Clean room classes D to A

Final products

• Soft-Mist-Inhaler (SMI)

• Eye drops

• IV bags

• Nasal dispensers

• Diagnostic strips

• Liquid tubes

Periphery

• Feeding technology

• Tray loader

• Assembly machines

• Packaging machines

Machine features

Parts handling

Components are automatically taken out using vacs, grippers or tongs and accurately transferred. This can be performed in a linear or swivel movement. To increase the output, these systems can be set up at multiple locations so as to perform loading and unloading tasks at the same time.

VIDEO

Related Searches

- Packing machine

- Automatic filler

- Automatic packing machine

- Bagging machine

- Liquid filler

- Automatic labelling machine

- FFS bagging machine

- Semi-automatic filler

- Film packing machine

- Bell type packing machine

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Labeller for the pharmaceutical industry

- Case packer

- Medical packing machine

- Checkweigher

- Automatic case packer

- Bag filler

- Packaging machine for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.