- Products

- Catalogs

- News & Trends

- Exhibitions

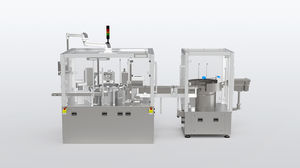

Automatic filling and sealing machine LRT-Abagliquidsfor pharmaceutical products

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Container type

- bag

- Fill product

- liquids

- Product applications

- for pharmaceutical products, for liquids

Description

The LRT-A is the ideal platform for the filling and sealing of infusion bags under sterile conditions in the medium performance sector. An integrated CIP/SIP system guarantees the cleaning of the filling path after each batch under immaculate hygienic conditions. Open RABS (Restricted Access Barrier System) technology with integrated laminar flow systems ensures the required aseptic conditions. The solution combines a sophisticated filling process with careful handling of the sensitive products. This meets the strictest requirements when working under sterile conditions.

Benefits

• Aseptic, pharmaceutically compliant GMP-design (EU GMP class A/ISO 5)

• 100% filling volume control

• Integration of state-of-the-art robot systems with safety control

• Aseptic solutions based on mature barrier technology

• Perfect accessibility

• Integrated lighting concept

• Numerous camera systems can be fully integrated

Technical data

• Output: up to 15 bags/min

• Filling volume: 25 – 250 ml

Final products

• Infusion bags

Periphery

• Feeding technology

• Tray loader

• Assembly machines

• Packaging machines

Machine features

Parts handling

Components are automatically taken out using vacs, grippers or tongs and accurately transferred. This can be performed in a linear or swivel movement. To increase the output, these systems can be set up at multiple locations so as to perform loading and unloading tasks at the same time.

Liquid dosing

Dosing systems for liquids are used in the form of modules in pharmaceutical and medical production platforms at Harro Höfliger. This way, custom project requirements can be tailored as needed.

VIDEO

Related Searches

- Packing machine

- Automatic filler

- Automatic packing machine

- Bagging machine

- Liquid filler

- Automatic labelling machine

- FFS bagging machine

- Semi-automatic filler

- Film packing machine

- Bell type packing machine

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Labeller for the pharmaceutical industry

- Case packer

- Medical packing machine

- Checkweigher

- Automatic case packer

- Bag filler

- Packaging machine for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.