- Products

- Catalogs

- News & Trends

- Exhibitions

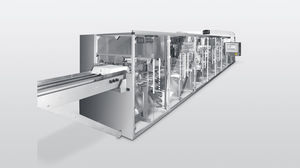

Horizontal cartoning machine KMFfor the pharmaceutical industrymedicalfully-automatic

Add to favorites

Compare this product

Characteristics

- Type

- horizontal

- Applications

- for the pharmaceutical industry, medical

- Other characteristics

- fully-automatic, bottle, continuous-motion

- Throughput

300 p/min

Description

With its special “air frame” folding box opening system, KMF gently and safely processes boxes with challenging profiles, finished surfaces and thick material. The bottles are carefully turned on their side and continuously inserted into the folding boxes. The boxes are then closed with a tuck-in or glue option

Benefits

• Solid construction – designed for continuous operation

• High output

• Fast and easy format change

• Parts that contact the product are made of wear resistant materials

• Safe and gentle folding box and bottle handling

• Protective sleeves can be processed as well

Technical data

• Weight: approx. 7,000 kg

• Air consumption: 20 NL/min.

• Bottle format: 0.3 l-1.5 l

Periphery

• Fully-automated loading system

• Feedscrew

• Oval motion with feed star

• Control systems

• Packaging machines for shipping boxes

Final products

• Spirits

• Champagne

• Fine beverage packagings

Machine features

Bottle supply

Feeding bottles at high speeds requires a precisely tuned motion sequence. For the cartoning process, bottles are separated. Bottle handling must be executed carefully to prevent the bottle from breaking.

Air Frame

Air flow in the opening process assists the mechanical process of opening folding boxes. This process enables the gentle forced opening of the packaging material even at high speeds. Refined folding boxes for the beverages industry, for example, can be optimally processed this way.

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Bagging machine

- Liquid filler

- Automatic labelling machine

- FFS bagging machine

- Semi-automatic filler

- Film packing machine

- Bell type packing machine

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Labeller for the pharmaceutical industry

- Case packer

- Medical packing machine

- Automatic case packer

- Checkweigher

- Bag filler

- Packaging machine for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.