- Products

- Catalogs

- News & Trends

- Exhibitions

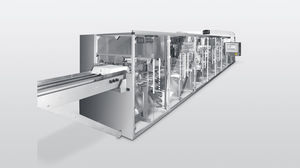

Automatic labeling machine MQSfor medical equipmentcartonfor the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product application

- carton, for medical equipment

- Applications

- for the pharmaceutical industry, for label print and apply application

- Other characteristics

- tamper-evident, vision system

- Throughput

300 p/min

Description

The Modular Quality System (MQS) is the ideal add-on component for your Harro Höfliger packaging line. All quality-relevant functions with regard to individual coding, labeling and protection against counterfeiting can be integrated in this modular platform. Of course, all applications are monitored by means of vision systems or sensors. This way, MQS combines all requirements for serialization and Unique Device Identification (UDI) in one machine.

Benefits

• Space-saving installation area

• Consistent "look and feel" in design, operating logic and documentation

• Precise and reliable product transport

• Format changeover is simple, fast and without any tools

• Fully integrated weighing cell

• Flexible integration of standard coding and camera systems

Technical data

• Format range: 5" and 7,5"

Machine features

Checkweigher

Integrated weighing cell for 100% weight control to check the presence of the product. Incorrectly filled cartons are marked in the system. They will not be further processed and are removed at the end of MQS.

Serializing

Our MQS can be easily equipped with serializing processes for the benefit of quality assurance and to increase protection from counterfeiting medicine. In the process, folding boxes are each marked individually and monitored by an image inspection system.

Printing

Multi-line systems enable coding of up to 300 cartons/min on both sides. In addition, the carton can be provided with a label.

Tamper-evident closure

Application of a tamper-evident seal increases protection against manipulation and counterfeiting.

VIDEO

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Bagging machine

- Liquid filler

- Automatic labelling machine

- FFS bagging machine

- Semi-automatic filler

- Film packing machine

- Bell type packing machine

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Labeller for the pharmaceutical industry

- Case packer

- Medical packing machine

- Checkweigher

- Automatic case packer

- Bag filler

- Packaging machine for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.