- Products

- Catalogs

- News & Trends

- Exhibitions

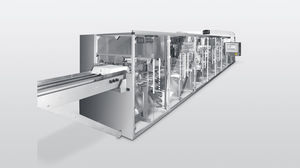

Top-loading cartoning machine MTLfor the pharmaceutical industrymedicalintermittent-motion

Add to favorites

Compare this product

Characteristics

- Type

- top-loading

- Applications

- for the pharmaceutical industry, medical

- Other characteristics

- intermittent-motion

- Throughput

60 p/min

Description

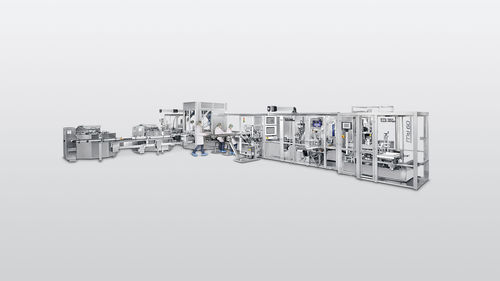

The MTL modular top-loader is suitable for the production of multi-component packagings. Products of different sizes or quality are loaded through individually designed feeding units. Carton inlays ensure an optimum hold of the package content. Manual infeed sections make it possible to flexibly equip the unit with additional components if necessary.

Benefits

• Modular design and modern balcony structure

• Optimum accessibility

• Fast format change with reproducible settings

• Many product options can be combined in a package

• Additional, switchable infeeds possible

Final products

• Syringes

• Tubes

• Bags

• Vials

• Inhalers

• Auto-injectors

Machine features

Top loading

During vertical cartoning, the box is first set upright, then adhesive is applied, it is filled from the top and finally closed. This method offers the advantage of being able to fill boxes in a variety of ways.

Product feeding

Product feeding plays a critical role in packaging machines. Harro Höfliger has a large repertoire of product handling systems. The feeding technology is configured individually depending on the requirements of the project and adjusted to the particular specifications.

Automation

Automated logistics concepts control how product components are fed via feeding unit and regulate the transport systems within the machine. Robot and automation technology is used to insert components into the packaging machine.

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Bagging machine

- Liquid filler

- Automatic labelling machine

- FFS bagging machine

- Semi-automatic filler

- Film packing machine

- Bell type packing machine

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Labeller for the pharmaceutical industry

- Case packer

- Medical packing machine

- Checkweigher

- Automatic case packer

- Bag filler

- Packaging machine for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.