- Products

- Catalogs

- News & Trends

- Exhibitions

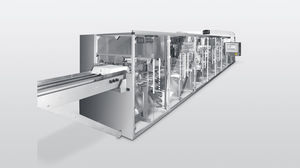

Rotary sealing machine PMK 4SSultrasonicautomaticbag

Add to favorites

Compare this product

Characteristics

- Type

- rotary, ultrasonic

- Operating mode

- automatic

- Product applications

- bag, edge, machine

- Other characteristics

- continuous-motion

Description

The rotation sealing machine PMK 4SS packages products in medical four-edge sealing bags. It reaches a yield of 400 bags/min, at a maximum sealing speed of 50 m/min. As a free-standing bag packaging unit, it can be quickly, reliably and reproducibly retrofitted for various bag sizes.

Benefits

• Modern balcony structure for optimum accessibility and maximum operator comfort

• Width and separation of the feeding can be adjusted without tools

• Fast and easy format adjustment (without format parts)

• Can be operated as free-standing sealing machine or integrated into a production line

• Crease-free sealing results

• Easy qualification by optimal distribution of the sealing temperature and sealing pressure

Technical data

• Output: up to 50 m/min. Hot sealing or up to 400 products/min. (depending on sealing material)

• Web width: from 75 - 400 mm, special design up to 500 mm

• Configuration: single track

Periphery

• Packaging machines

• Labeling systems

• Control systems

Final products

• Four-edge sealing bag

Machine features

Aseptic bagging

Product packaging in bags plays an important role in product protection and in ensuring sterility. Sophisticated sealing and cutting components guarantee a high performance packaging process – from small to large format applications.

In-line printing

Products can be coded at various positions during the process. Film components or bag webs are printed with a batch code or information about the product quality. Harro Höfliger uses the popular systems thermotransfer, Inkjet or laser.

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Bagging machine

- Liquid filler

- Automatic labelling machine

- FFS bagging machine

- Semi-automatic filler

- Film packing machine

- Bell type packing machine

- Horizontal bagging machine

- Filler for the pharmaceutical industry

- Sealer

- Labeller for the pharmaceutical industry

- Case packer

- Medical packing machine

- Automatic case packer

- Checkweigher

- Bag filler

- Packaging machine for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.