- Materials - Tools - Components

- Lubrication

- Oil lubrication unit

- HOERBIGER Automatisierungstechnik GmbH

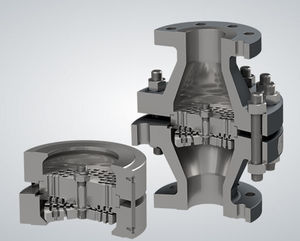

Oil lubrication system XperLUBEhydraulicautomatic

Add to favorites

Compare this product

Characteristics

- Lubricant

- oil

- Power source

- hydraulic

- Other characteristics

- automatic

Description

If you want to bring cylinder lubrication and compressor operation into a harmonious relationship,

.....you have to separate oil pressure generation and oil injection correctly.

Reliable cylinder lubrication is one of the most sensitive issues for the operation of highly sophisticated reciprocating compressors. The wrong dosage can cause damage through wear or overlubrication. This means: unscheduled downtime, costly production losses or consequential damage in other parts of the production.

Time to delegate this important task. To the expert. The HOERBIGER XperLUBE system is designed to increase the performance and cost efficiency of your compressors. XperLUBE supplies your system with exactly the right amount of lubricant. Always. Under all conditions.

XperLUBE is modern lubricant management. Temperature, pressure, speed or even the failure of a lubrication point: XperLUBE is faster and more precise than manual service. According to your parameters, XperLUBE automatically adjusts the system's lubricant supply to changing conditions.

XperLUBE. One less worry. All parts are standardized and can be replaced individually. This simplifies stock-keeping, reduces inventory and storage costs.Replacing individual components is quick and easy. Therefore, XperLUBE is also suitable for retrofitting already installed systems. XperLUBE offers closed-loop control of the amount of oil introduced at each lubrication point, simple external influencing of the lubrication quantity, and a significant improvement in fault detection capabilities.

VIDEO

Catalogs

XperLUBE

8 Pages

Other HOERBIGER Automatisierungstechnik GmbH products

Components and services for compressors

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.