- Robotics - Automation - Industrial IT

- Automation

- Process control system

- HOERBIGER Automatisierungstechnik GmbH

Process control system HydroCOMelectricindustrialautomatic

Add to favorites

Compare this product

Characteristics

- Function

- process

- Type/technology

- electric

- Product applications

- industrial

- Other characteristics

- automatic

Description

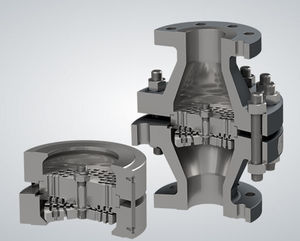

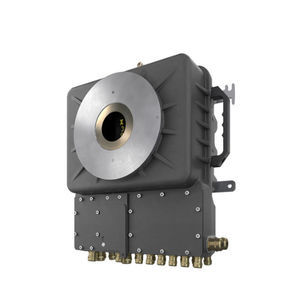

HydroCOM is a stepless and fully automated capacity control system for reciprocating compressors. Often a reciprocating compressor delivers more gas than required by the process. This causes due to the physics and design of the compressor as well as the fluctuations in the process. The operating principle of the HydroCOM is based on the reverse flow principle. This means that only the gas flow that is needed for the process is compressed. This avoids the reuse of process gas and the cost of electrical energy for the driver can be significantly reduced, thus increasing the profitability of your plant.

When efficient part load is required, the HydroCOM system allows a simpler compressor design, with significantly fewer cylinders, compared to on/ off control. In addition, individual adaptation, to your needs, of the hydraulic unit is possible.

How does the HydroCOM system work?

Around 1,600 systems are currently in reliable operation. The hydraulic HydroCOM actuators enable fast and precise control without any loss of performance, if required even from 10* to 100 percent within three revs. The wide, stepless volume control range thus ensures optimum process control. Thanks to the interface to PLC or process controller, the HydroCOM allows fully automated control. Reliable and standardized components drastically minimize the risk of unplanned downtime.

Modular system

Due to its modular design HydroCOM is easy to integrate into both existing and new compressor installations.

Other HOERBIGER Automatisierungstechnik GmbH products

Components and services for compressors

Related Searches

- Industrial remote control

- Remote control with buttons

- Industrial control system

- Rugged remote control

- Automatic control system

- Cable remote control

- Process control system

- Machinery remote control

- Automatic control panel

- Electric control system

- Gas pressure controller

- Mining equipment remote control

- Precision pressure controller

- Remote control with touchscreen

- Logistic remote control

- Antenna remote control

- Remote control for medical applications

- Mobile remote control

- Automobile remote control

- Proportional pressure controller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.