- Hydraulics - Pneumatics

- Valve

- Gas relief valve

- HOERBIGER Automatisierungstechnik GmbH

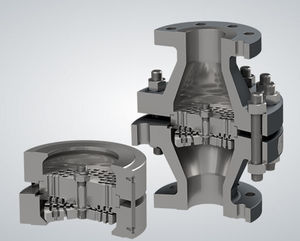

Gas relief valve CT for compressors

Add to favorites

Compare this product

Characteristics

- Fluid

- gas

- Applications

- for compressors

- DN

Max.: 221 mm

(8.701 in)Min.: 77 mm

(3.031 in)- Pressure

350 bar

(5,076.3 psi)

Description

Reliable performance for over 25 years

The HOERBIGER CT valve is suitable for virtually all applications that employ short-stroke, high-speed gas compressors. Millions of CT valves are operating successfully in the natural gas processing industry.

Its plate type valve design is optimised to utilize the properties of non-metallic valve plates and has proven its performance for years. The single moving sealing element of the CT valve allows easy maintenance (field repairable).

Why HOERBIGER CT Valve?

The CT valve proves operational excellence even in heavy duty upstream natural gas applications.

Plate design and spring arrangement result in unique and smooth valve motion even in high-speed, lubricated service.

Properly selected valve materials ensure safe operation even in sour environment.

This is how the CT valve works

The plastic valve plate, in conjunction with a wafer spring, dampens the opening impact.

At high rotational speeds, the wafer spring prevents oil sticktion of the valve plate.

Closing springs on the outside guarantee largely wobble-free valve plate movement and consequently long valve service life.

Excellent flow efficiency for low power consumption

Long life even in difficult and contaminated conditions

Best suited for changing operating conditions

Proven in lubricated and non-lubricated operation

Resistant to gas impurities and oil sticktion

High operating temperatures

Catalogs

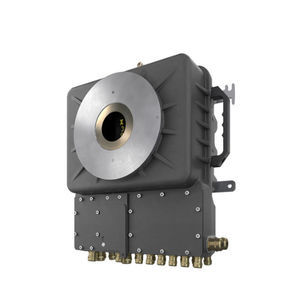

Other HOERBIGER Automatisierungstechnik GmbH products

Components and services for compressors

Related Searches

- Valve

- Control valve

- Valve with flange

- Flap valve

- Non-return valve

- Electric valve

- Directional control valve

- Valve actuator

- Compact valve

- 3-way valve

- Fluid check valve

- Electric valve actuator

- Pneumatic directional control valve

- Relief valve

- Plunger valve

- High-pressure valve

- Small valve

- Spring non-return valve

- Spool pneumatic directional control valve

- Electrically-operated pneumatic directional control valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.