- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Plate heat exchanger

- Hofmann (Beijing) Engineering Technology Co., Ltd.

- Company

- Products

- Catalogs

- Projects

- News & Trends

- Exhibitions

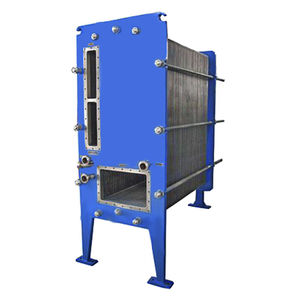

Plate heat exchanger HFM25B Plate heat Exchangerliquid/liquidindustrial

Add to favorites

Compare this product

Characteristics

- Type

- plate

- Fluid

- liquid/liquid

- Applications

- industrial

Description

Recommended Applications: The plate heat exchangers of the HFM25B series are designed for high pressure. They can be used for

heating and cooling operations in multiple areas, steam condensation, milk pasteurization, industrial circulating water cooling and other clear media’s heating and cooling.

HFM25B plate heat exchanger’s muti-section design for milk pasteurization has the advantages in less space taking, more efficient heat transfer, and economic cost control.

Design Priciple:

HFM25B plate range with length 0.87m, will cover many duties up to 140m3/h in a single pass solution, satisfying many applications requirement.

By means of countercurrent flow, the hot side medium transfers thermal to the cold side medium through plates between channels. And the media do not mix with each other to achieve optimal heat exchange efficiency.

For the one pass solution design, all connections are on the fixed frame side which will easier the plate heat exchanger installation and disassembling. When do cleaning and maintenance jobs, no need to remove the pipes.

Flow plates:

The plate design has two corrugated forms: horizontal corrugated and vertical corrugated. The plates can meet different pressure drop requirements and suit for different working conditions media.

The corrugated “herringbone” pattern makes more contact points between plates bearing more uniform pressure and ensures turbulent flow in the

whole effective area.

Data Required for Correct Quotation

Types of Media

Working Pressure

Pressure Loss

Thermodynamic properties

Temperatures

Flow rates

Above data determines the choice of heat exchanger.

Catalogs

HFM25B Plate heat Exchanger

2 Pages

Other Hofmann (Beijing) Engineering Technology Co., Ltd. products

Heat Exchanger

Related Searches

- Heat exchanger unit

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Industrial heat exchanger unit

- Compact heat exchanger unit

- Process water cooler

- Copper heat exchanger

- Brazed plate heat exchanger

- Condenser

- Liquid evaporator

- Heat exchanger for the chemical industry

- Pressure heat exchanger

- Nickel heat exchanger

- Heat exchanger for the pharmaceutical industry

- High-pressure heat exchanger

- Heat exchanger for the petrochemical industry

- High-temperature heat exchanger

- Heat exchanger for the automotive industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.