These furnaces are ideally suited for the heat treatment of individual pieces or small quantities. They are designed for use on different materials such as metal or ceramics.

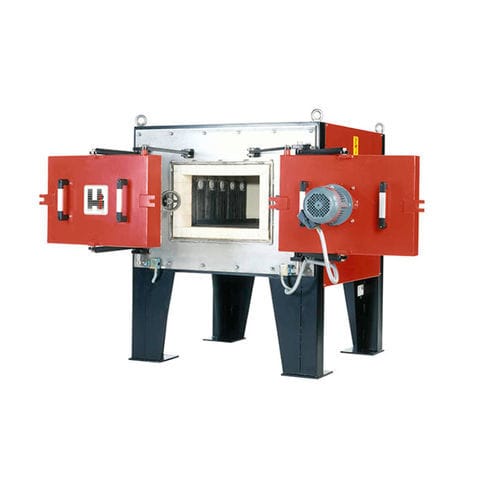

Chamber oven K:

The chamber furnace is used specifically for the heat treatment of metal under radiant heat. If such furnaces are used for tempering after hardening to relieve thermal stresses, then a separate door design is available. In this case, a second door with a circulating air fan is attached to the furnace, which can be activated if necessary. The long-life, deformation-resistant HOFMANN vertical heating modules are used in the chamber furnace.

Chamber oven K:

The kiln comes from a long tradition. Its robust design makes it ideally suited for use in commercial and industrial environments. With the available options, firing furnaces can be optimized for any application. They are often used for firing ceramic materials. Sophisticated control technology is offered especially for the field of industrial ceramics. The patented HOFMANN vertical heating modules are also used in the firing kiln.

Chamber oven K:

An air circulation furnace is mainly used for heat treatment at temperatures up to 600°C. The furnace is equipped with an inner housing made of stainless steel and heating is usually carried out electrically by means of tubular heating elements.

Heat energy generated inside the furnace is transferred to the workpieces by the air flow moved by an electric fan. The air flow through the furnace chamber can be either vertical (circulating air) or horizontal (cross air).

Special designs (according to DIN EN 1539) allow this type of oven to be used as a paint drying oven.