- Materials - Tools - Components

- Standard Mechanical Component

- Metal seal

- Holland Shielding Systems BV

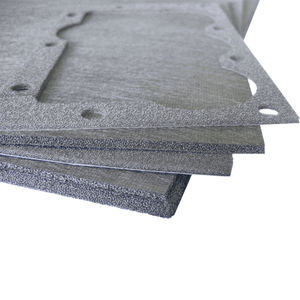

Metal gasket 1200 series meshfor doorsfor heavy-duty applications

Add to favorites

Compare this product

Characteristics

- Material

- mesh, metal

- Application

- for doors, EMI shielding, for heavy-duty applications

- Other characteristics

- conductive, knitted

- Temperature limit

Min.: -60 °C

(-76 °F)Max.: 180 °C

(356 °F)- Diameter

Min.: 1.6 mm

(0.063 in)Max.: 4.8 mm

(0.189 in)

Description

The knitted wire mesh EMI/RFI shielding gaskets consist of a layer of knitted electrically conductive metal wires attached to a low-closure force rubber or elastomer core. For heavy-duty applications like EMP or high temperatures, a full metal version is available. Sometimes a Metal knit EMI/RFI gasket is combined with an environmental seal to provide IP rating, depending on the materials used.

Knitted wire mesh gaskets provide a cost-effective solution to high shielding performance applications in the magnetic and electrical fields, including EMP. The gaskets can be made either completely from knitted metal mesh or from knitted metal mesh over an elastomer core which allows recovery after compression.

For high-frequency shielding, foil-based gaskets like Amucor Shield will perform better, because of their much larger contact surface.

Benefits

• High attenuation for lower frequencies (low-frequency magnetic shielding)

• Suitable for use under extreme conditions (military applications)

• Wear-resistant

• Not susceptible to corrosion

• Various conductive materials against tension corrosion

• Roll lengths of 1 to 1000 meters (depending on width and height of the gasket)

• Tools required: pair of scissors

Catalogs

innovative EMI shielding solutions

286 Pages

EMI shielding catalog

64 Pages

Other Holland Shielding Systems BV products

EMI shielding gaskets

Related Searches

- Conduit gland

- Waterproof cable gland

- Metal cable gland

- Polymer seal

- IP68 cable gland

- Lip seal

- Nickel-plated brass conduit gland

- Metal seal

- Cable entry plate

- Rubber gasket

- EPDM gasket

- Silicone gasket

- Polyurethane gasket

- V seal

- EMC-shielded cable gland

- Shielding gasket

- Profiled gasket

- Threaded conduit gland

- EMI shielding gasket

- Conductive gasket

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.