- Materials - Tools - Components

- Semi-finished products

- Electrically-conductive coating

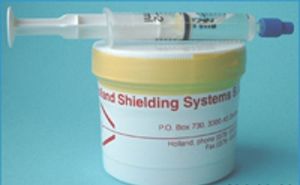

- Holland Shielding Systems BV

Electrically-conductive coating 3801 seriesnickel

Add to favorites

Compare this product

Characteristics

- Function

- electrically-conductive

- Material

- nickel

Description

Electrically conductive nickel coating

For EMI/RFI shielding of plastic housings and plastic components

Electrically conductive nickel coating 3800 series is a fast and easy way for EMI/RFI shielding/screening of plastic enclosures/housings. Shielding electrostatically sensitive applications can be done by using a electrically conductive paint containing nickel, copper or silver.

The paint comes in aerosols (part number 3801) for easy use, but can also be supplied in tins of 5 liters, 7 kg (part number 3805) and tins of 20 liters, 28 kg (part number 3820) for larger quantities. Materials such as iron-chrome-aluminum and molybdenum-disilicide are used for higher temperature applications.

Some oxide ceramics are used as conductors and semi-conductors for specialized applications. To fulfill the requirements concerning the limits of immunity and emission to interference, plastic housings and components needs to get fully or selectively electrically conductive coated. The nickel conductive coating contained in an air-drying acrylic resin.

The resin becomes touch dry 15 minutes after application and achieves maximum conductivity within 24 hours. It is intended to prevent electrical interference, penetrating enclosures fabricated from thermoplastics and other insulating materials. The coating will also prevent static build up.

It is recommended that an earth connection is made to achieve maximum shielding performance. A suitable material is part number 3201 Copper shielding tape which may simply be pressed on the coated surface or over-sprayed with the electrically conductive nickel coating. The applied coating has a mat gray textured finish.

Catalogs

No catalogs are available for this product.

See all of Holland Shielding Systems BV‘s catalogsOther Holland Shielding Systems BV products

Conductive coatings & glue

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.