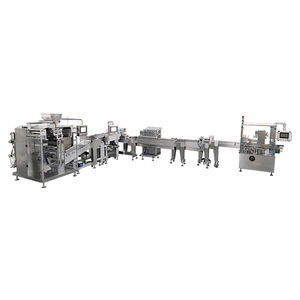

Automatic packaging machine MD6330continuousfilmliquids

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Type

- film, continuous

- Applications

- liquids, for the food industry, coil

- Domain

- for the food industry, medical, for the pharmaceutical industry

Description

Suitable for high viscosity liquid such as tomato sauce, tomato juice, mayonnaise, mustard, seasonings, shampoos, toothpaste, beauty boxes, syrups, ointments, gels, etc.

Features

Easily operated and user-friendly. Easy to adjusts the materials weight, temperature and packaging speed.

Plunger pump is used to lift, which is suitable for high viscosity liquid with high precision; The structure of the pump is quick-connect disassemble, which is convenient for cleaning and disinfection.

Online real-time monitoring of material shortage, film shortage and heating block, and the LCD screen real-time displays the alarm and its alarm cause.

Filming from low upper is more convenient and efficient. It is simple to remove, and convenient for maintenance.

The pump body is stainless steel for environmental protection. It uses 304 stainless steel liquid to store tank. Equipped with compartment heating and stirring function. Temperature is accurately controlled at 20-100°C, which is more suitable for all kinds of material packaging.

Servo motor controls continuous film feeding. Stable tension of the film. Real-time calculation of the coil diameter.

Filling head is made of PTFE, featuring corrosion resistance, wear resistance, high temperature resistance. It can be used for filling materials in high temperature (below 95°C). It is equipped with anti-drip module.

Data transmission function, realizing remote monitoring and data analysis management.

Catalogs

No catalogs are available for this product.

See all of Hollysys‘s catalogsRelated Searches

- Packing machine

- Automatic packing machine

- Packing machine for the food industry

- Film packing machine

- Packaging machine for the food industry

- Bag packing machine

- Medical packing machine

- Horizontal packing machine

- Packaging machine for the pharmaceutical industry

- Compact packing machine

- Granular packing machine

- Manual packing machine

- Packaging machine for the chemical industry

- Liquids packing machine

- Continuous packaging machine

- Hygiene product packaging machine

- Coil packing machine

- Tea packing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.