- Detection - Measurement

- Flow, Pressure and Level Measurements

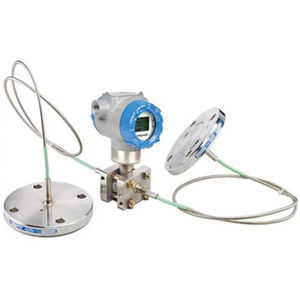

- Liquids level gauge

- Honeywell Advanced Sensing Technologies

Liquids level gauge electronicfor shipsexplosion-proof

Add to favorites

Compare this product

Characteristics

- Fluid

- liquids

- Technology

- electronic

- Applications

- for ships

- Other characteristics

- stainless steel, explosion-proof, high-pressure, portable, intrinsically safe

Description

A solution that makes possible the compulsory gas-tight gauging and sampling operations, at high pressure, while maintaining the intrinsically safe design for explosion safety.

Shuttle tankers and parcel (chemical) tankers operators , facing stringent regulations, must reduce the amount of VOC gas (Volatile Organic Compound) released during loading operations. The threshold of the pressure-relief valves, and the pressure of Inert gas, moves from the standard 0.18 to 0.25 bar to up to 0.7 bar. Specially designed ships with reinforced tanks are built for this purpose.

The challenge is to assure the compulsory gas-tight gauging and sampling operations, at high pressure, while maintaining the intrinsically safe design for explosion safety.

What Is It?

The high pressure gauging and sampling solution comprises 4 components :

The Deck Valve:

Made of stainless steel with high Molybdenum content and PFTE seals: it ensure easy sampling operations and prevent against water contamination and release of gases.

The UTImeter Gauge:

Ullage, Temperature, Interface.This model has been reinforced to maintain gas tightness, while staying lightweight and easy to operate.

The Sampler:

The Hermetic sampler GTX CHEM 0.7 bar is designed for the maximum security of operations while keeping the operations simple and quick.

The DIP:

The HERMetic DIP 2 GT 07bar 30m allows checking on the presence of sediments at the bottom of the tank

What Problems Does It Solve?

Shuttle and parcel tankers operators compliance with environment and MARPOL regulations

Gas-tightness has to be maintained during gauging and sampling operations

Intrinsic safety against explosive atmospheres hazards

Catalogs

No catalogs are available for this product.

See all of Honeywell Advanced Sensing Technologies‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Honeywell Advanced Sensing Technologies products

Marine

Related Searches

- Honeywell pressure transmitter

- Level limit switch

- Level probe

- Liquid level limit switch

- Honeywell analog pressure transmitter

- Liquid level probe

- Pressure switch

- Pressure probe

- Waterproof pressure transmitter

- Stainless steel pressure transmitter

- Membrane pressure transmitter

- Analog level probe

- Honeywell relative pressure transmitter

- Protection level level switch

- Mechanical pressure switch

- Honeywell digital pressure transmitter

- Level transmitter

- Stainless steel level limit switch

- Liquid level transmitter

- Gas pressure transmitter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.