- Products

- Catalogs

- News & Trends

- Exhibitions

Stainless steel drying cabinet stationary

Add to favorites

Compare this product

Characteristics

- Configuration

- stainless steel

- Portability

- stationary

Description

The basic configuration of our drying cabinets and drying chambers is also defined in the same way. We offer you:

Stainless steel inner housing – resistant to aggressive media and easy to clean

Heating via tubular heating elements in the cross-flow of the circulating air turbines

Powerful air circulation turbines and motors

Horizontal air circulation, with wall preheating

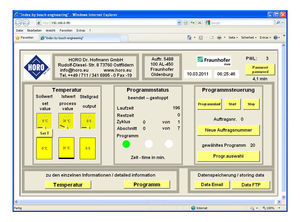

Electronic control with high-quality PID controllers with self-optimisation

High-quality PT 100 sensors in 3-wire connection

Temperature limiter according to EN 60519-2, class 2, for product protection

We basically offer three series: each for a maximum temperature of up to 250 degrees Celsius, 400 degrees Celsius and 650 degrees Celsius.

Drying chamber type “H-Dry”: conventional, but efficient

The conventional drying chamber or the “H-Dry” drying cabinet or laboratory drying cabinet variant works according to the standard principle:

Ambient air is drawn in, heated and fed into the drying chamber so that the product moisture can be absorbed and removed via the exhaust air. This is inexpensive to purchase, but often somewhat more demanding in terms of energy consumption. H-Dry is therefore energy-optimised and offers high performance with manageable energy requirements.

K-Dry drying cabinet: for high requirements and lower energy consumption

K-Dry is a drying cabinet for relatively high humidity with moderate temperature and energy requirements. The K-Dry is used for drying dripping wet parts. The “K-Dry” has a drying air generator, but works with a cold trap and heat pump, so that a lot of water can be separated in an energy-saving way and at the lowest moisture level.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.