- Machine-tools

- Machine Tool Accessory

- Vacuum chuck

- Horst Witte Gerätebau Barskamp KG

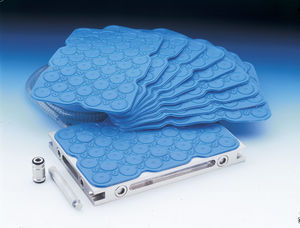

Vacuum chuck Microporous

Add to favorites

Compare this product

Description

Witte microporous vacuum chucks are the ideal solution for clamping and fixing for measuring and test procedures, for precision machining and in silicon wafer production. Substrates such as RFID films or wafers are not deformed by suction holes, suction grooves, etc.

Witte microporous chucks can be heated or cooled, each with appropriate controls. Special systems for transmitted light applications are also available. For microporous surfaces Witte offers a wide variety of materials, for example sintered bronze, ceramics or aluminum. Even black and fluorescent clamping surfaces are available.

measuring, checking and machining of thin-walled substrates (e.g., papers, foils, circuit boards, wafers, PCB boards),

fine (e.g., optics) and

flexible (e.g., rubber) materials

measuring and testing

pecision machining

silicon wafer production

no deformation of the workpieces, as there are no grooves or holes

recessing possible when using a Friction Booster

METAPOR © plates available in different qualities

Handling

modular versions for large clamping surfaces

workpiece-specific custom built chucks possible

Vacuum clamping technology

METAPOR © vacuum clamping systems are characterized by full-surface suction without any bores. Films and foils can be clamped absolutely flat. The pressure drop in the structure makes covering of free surfaces obsolete. METAPOR © is excellently suited for fixing foils and electronic parts as well as a gripper for soft objects.

Catalogs

Other Horst Witte Gerätebau Barskamp KG products

Vacuum clamping technology

Related Searches

- Clamp

- Base plate

- Clamping plate

- Clamping fixture

- Rectangular clamping plate

- Fixture

- Mechanical clamping fixture

- Vacuum chuck

- Workpiece clamping fixture

- Modular clamping plate

- Square clamping plate

- Aluminium clamping plate

- Round clamping plate

- Anti-slip base plate

- Grinding vacuum chuck

- Workpiece vacuum chuck

- Milling vacuum chuck

- Engraving vacuum chuck

- Large clamping plate

- Circular vacuum chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.