- Power Transmission - Mechanical components

- Mechanical Transmission

- Vacuum clamping system

- Horst Witte Gerätebau Barskamp KG

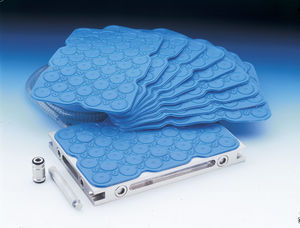

Vacuum clamping system FLIP-PODadjustableeccentricmodular

Add to favorites

Compare this product

Characteristics

- Type

- vacuum

- Other characteristics

- adjustable, eccentric, modular

Description

The vacuum system FLIP-POD is mainly used for milling, drilling and thread cutting on large workpieces made of wood, plastic, glass, metal and cast iron.

FLIP-POD fixes the workpiece via suction cup-like pods embedded in the vacuum chuck. They create the contact points to the component, via which it is sucked down and clamped. Pods not required are stored upside down in the cavities of the pod chuck and lie there until required for use with other part geometries.

Flip-pod is available in numerous variations such as half and three-quarter pods, eccentric and even height-adjustable.

milling (pockets, through and contour milling)

drilling

threading

recessing

of large workpieces made of

wood

plastic / glass

metal

cast

also with sawn, rough and non-machined surfaces

extrusions

high downforce enables use on large machines

machining chamfers, radii and recesses possible on the outer contour of the workpiece on the top and underneath

individual adaptation to the respective clamping situation

Handling

pods serve as support for the workpiece to be clamped

easy activation of individual pods by flipping over

modular system, extendable for large clamping surfaces

VIDEO

Catalogs

Other Horst Witte Gerätebau Barskamp KG products

Vacuum clamping technology

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.