- Packing - Handling - Logistics

- Conveying

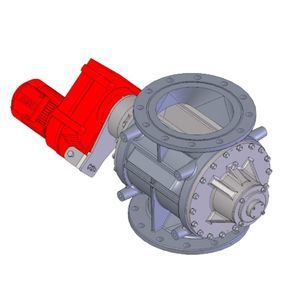

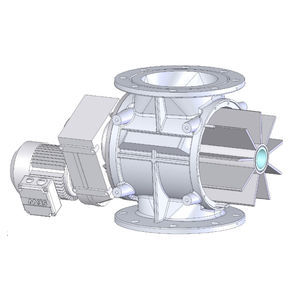

- Pneumatic conveying rotary valve

- HOSOKAWA SOLIDS, S.L.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Rotary valve for pharmaceutical applications ZRSfor pneumatic conveyingpowderfor heavy-duty applications

Add to favorites

Compare this product

Characteristics

- Applications

- for pharmaceutical applications, for pneumatic conveying, powder, for heavy-duty applications, for bulk materials, sanitary, for food, multi-purpose, for grain, for pellets, for plastics, for chemical products, for dust collectors

- Type

- gravity

- Other characteristics

- explosion-proof, ATEX, electrically-actuated, manual, pneumatically-actuated, with cutting device, hygienic, multi-channel

Description

Dosing rotary valve, low pulsation where applicable with plenty pockets rotor, ideal for products wich are tending to extreme flow.

• Sturdy and less wear

• Cost-effective and low maintenance due to simple assembly

• Space-saving

• Gas-tight from outside

• Safety for operators, with a DMT certificate

Generally a rotary valve has two basic functions: Discharging and metering. Both the functions have an additional task to establish an air lock point between two sections of the system.

Absolute air lock is however not possible at the given pressure difference. The flow of the

leakage air can only be minimised.

Discharge

The basic function of pure discharging is executed by the well-known basic rotary valve: In the housing the rotor is revolving by constant speed. Due to gravity the product comes out from the container or the hopper from the top and falls in the chambers of the rotor. Due to the revolving rotor the product is transported to the discharge opening, from where it again moves down by gravity. The rotary valve itself does not affect the flow capacity of bulk solids. It depends on the chamber volume, filling ratio and rotation speed.

Metering

The rotary valve for metering is characterised by a variable speed, e.g. using a variable-pitch

geared motor or a frequency converter drive. The metering is purely volumetric in such a case: A specific volumetric flow per time unit is set as the desired value in dm ³/s or m³/h. It is however not measured so that there is an undefined deviation between the desired and actual values.

Catalogs

No catalogs are available for this product.

See all of HOSOKAWA SOLIDS, S.L.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.