- Packing - Handling - Logistics

- Conveying

- Filled container unloading system

- HOSOKAWA SOLIDS, S.L.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

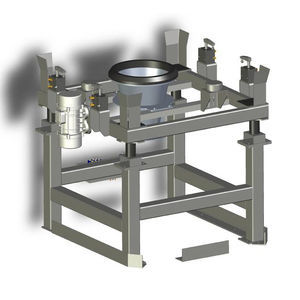

Big bag unloading system BAB seriesfor hopperhandlingsilo

Add to favorites

Compare this product

Characteristics

- Product applications

- for big bags, for hopper, handling, silo, drum, for cosmetic products, for the food and beverage industry, for bulk materials, for filled containers, for the petrochemical industry, for trucks, for adhesive materials, for sacks

- Other characteristics

- automatic, modular, pneumatic, vibrating

Description

Economic solution: big-bag support plate with base frame.

Options: discharge aid vibration hopper with unbalanced motor or tumbling device with pneumatic cylinder and punching tool, discharge hopper.

• Fail-safe

• Efficient working without interrupting the process: the buffer container can be used for discharging when changing a big-bag

• Easy-to-operate due to wide pivoted doors

• Less dust due to a special seal between the big-bag bottom and the support shell, connection to extraction provided by customer or additional extraction filter

• Low maintenance

permissible operating pressure: atmospheric, product temperature max: 40° C

max./min. ambient temperature: -10 °C ≤ T ≤ 50 °C

Bulk solids are discharged from: Big bags, containers, sacks, or barrels. The reliable and usable complete solution provides Big bag attachment, dustproof connection, discharging and integrated control.

The container to be discharged is moved into a suitable position. Then the solid goods are discharged, either by free-fall or using a discharging device or metering device. Frequently, a discharging tool is required to facilitate product flow and to ensure a complete discharge.

Catalogs

No catalogs are available for this product.

See all of HOSOKAWA SOLIDS, S.L.‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Horizontal rail conveyor

- Grinding mill

- Conveyor for the food industry

- Stainless steel weighing scale

- Electric drive conveyor

- Kg weighing scale

- Industrial weighing scale

- Horizontal grinding mill

- Inclined conveyor

- Waterproof weighing scale

- Stainless steel conveyor

- Food lump breaker

- Electronic weighing scale

- Precision balance

- Bulk products conveyor

- Benchtop balance

- Screw conveyor

- Weighing scale for the food industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.