- Packing - Handling - Logistics

- Conveying

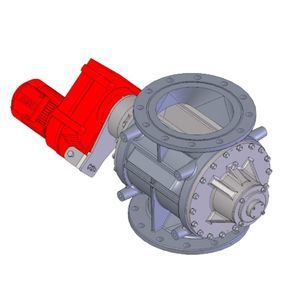

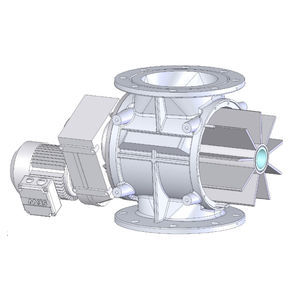

- Pneumatic conveying rotary valve

- HOSOKAWA SOLIDS, S.L.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Hygienic rotary valve SRVP seriesfor pneumatic conveyingfor dust collectorsfor food

Add to favorites

Compare this product

Characteristics

- Applications

- for pneumatic conveying, for bulk materials, powder, for food, for pharmaceutical applications, for plastics, for chemical products, multi-purpose, for dust collectors

- Type

- round-flange

- Other characteristics

- ATEX, explosion-proof, electrically-actuated, pneumatically-actuated, manual, hygienic

Description

Rotary valve for discharge and feeding, suitable forn feeding in pressure- or suction conveying lines, hygienicversion acc. EHEDG-Guidelines with certificate type EL-Class II, as protective system acc. ATEX for products with dust explosion risk.

• Fulfills GMP- / FDA-requirements, DIN EN 1672-2 (food machines) and DIN EN ISO 14159 (hygienic requirements)

• Easy dismantling, easy cleaning

• Simple and time-saving disassembly and assembly of the rotor without adjustment of the clearance between rotor and housing

• Suitable for wet cleaning in assembled condition (CIP) with following inspection and secondary cleaning, if necessary

• In contact with product surface quality acc. ≤ 0,8µm

• Weldings free of gaps and scattered (≤ 0,8µm)

• Corners and edges with big radius

• Easy to dismantle and to clean

Maximum pressure: 0,9 bar absolute up to <1,5 bar g.

Product temperature from -20°C up to 120°C with corresponding clearance for constant operating temperature.

According to EHEDG-guidelines type EL-Class II, machinery directive 2006/42/EC, DIN EN ISO 14159 (hygienic requirements), DIN EN 1672-2 (food machinery) and GMP/FDArequirements.

Housing: casted stainless steel 1.4408 (DIN) / CF-8M (AISI).

Rotor: welding construction – stainless steel 1.4307 (DIN) / 304L (AISI). 8 rounded pockets, rotor extensible without leading rails.

Outside bearings.

Catalogs

No catalogs are available for this product.

See all of HOSOKAWA SOLIDS, S.L.‘s catalogsRelated Searches

- Rail conveyor

- Grinding mill

- Conveyor for the food industry

- Stainless steel weighing scale

- Electric drive conveyor

- Industrial weighing scale

- Kg weighing scale

- Horizontal grinding mill

- Waterproof weighing scale

- Stainless steel conveyor

- Food lump breaker

- Electronic weighing scale

- Precision balance

- Bulk products conveyor

- Benchtop balance

- Screw conveyor

- Weighing scale for the food industry

- Loading and unloading system

- Roller grinding mill

- Compact balance

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.