- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Electric coil heater hotspring

Add to favorites

Compare this product

Characteristics

- Setting speed

- electric

Description

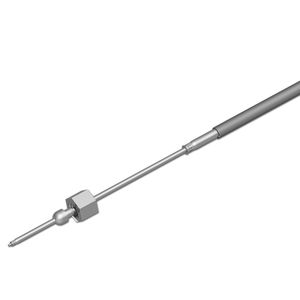

hotset was already in 1980 one idea ahead as they presented the first round hotspring coil heater. Since then further innovations have been made: hotspring®/Mini (type WRP 1,3 x 2,3), flat and square, hotspring®/Maxi (type WRP 4,8 x 8,6) as well as hotspring®/Micro (type WRP 1,3 x 2,3).

This innovation as well as the humidity-resistant coil heaters according to I.P. 65 (type WRP/F 2.2 x 4.2 - WRP/Q 3.0 x 3.0) emphasize the consequente alignment to new challenges.

Application examples

• - Mass channel Technology - Heating of manifolds

• - Packaging Industry - Heating of welding bars

• - Mass channel Technology - Heating of mass channel nozzles

• - Packaging Industry - Heating of sealed heads

hotset presents a wide product spectrum of hotspring®coil heaters:

• - Starting with hotspring®/Micro (type WRP/F 1,0 x 1,6) up to hotspring®/Maxi (type WRP 4,8 x 8,6) with different lenghts and diameters

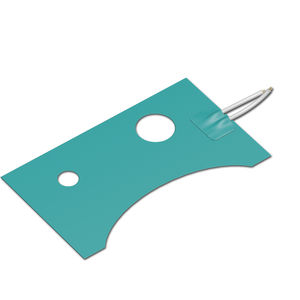

• - Coil heaters with clamping mechanism as heating elements for different applications

• - Heating systems such as the hotcast® sealed heater (type GMH)

• - Special products such as hotslot®

• - As well as a wide spectrum of applications.

Stock Range

To find your favorable item from stock please see brochure download on the right. Stock items are at pages 4 - 7. Please request stock items by the default contact form.

hotspring® with reflection tube

When using hotspring® coil heaters with a reflection tube the maximum surface load increases. Furthermore the reflection tube protects the heater from mechanical damages. The reflection tube can be delivered for a lot of hotspring® dimensions.

Catalogs

Related Searches

- Resistance heater

- Tubular resistance heater

- Cartridge heater

- Flat resistance heater

- Laboratory hot plate

- Flexible resistance heater

- Industrial resistance heater

- Silicone resistance heater

- Resistance heater with thermostat

- Custom resistance heater

- Finned resistance heater

- Coil heater

- Heat treatment hot plate

- Adhesive heating element

- Automotive heating element

- High-temperature cartridge heater

- Heating element for medical applications

- Soldering hot plate

- Multi-zone heating element

- Cast-in resistance heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.