- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Cast-in heating element hotcast

Add to favorites

Compare this product

Characteristics

- Type

- cast-in

- Maximum temperature

750 °C

(1,382 °F)

Description

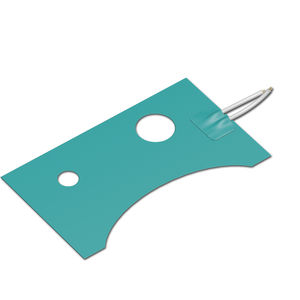

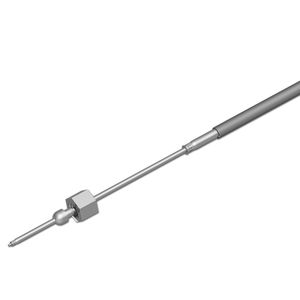

hotcast Sealed Heater

hotset offers a wide product range for applications in the casting industry (e. g. hot chamber casting).

The hotcast Sealed Nozzle Heater (type GMH) based on the heating with a hotspring Maxi with power distribution offers the possibility of an equal heating of the mass channel. The densely welded sealed system grants besides resistance against penetrating material, high energy savings (up to 60 % towards traditional heating) as well as shorter cycle times and material savings (shorter sprue bar and shorter cycles by deep immersion into the tool).

The hotcast Open Ended Nozzle Heater (type OMH) offers a favourable alternative to the sealed system.

Catalogs

Related Searches

- Resistance heater

- Tubular resistance heater

- Cartridge heater

- Flat resistance heater

- Laboratory hot plate

- Flexible resistance heater

- Industrial resistance heater

- Silicone resistance heater

- Resistance heater with thermostat

- Custom resistance heater

- Finned resistance heater

- Coil heater

- Heat treatment hot plate

- Adhesive heating element

- Automotive heating element

- High-temperature cartridge heater

- Heating element for medical applications

- Soldering hot plate

- Multi-zone heating element

- Cast-in resistance heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.