- Environment - Health - Safety

- Air Treatment and Noise Management

- Floor-standing fan

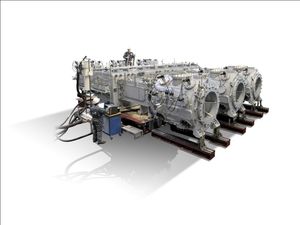

- Howden BC Compressors

Floor-standing fan centrifugalsteelcomposite

Add to favorites

Compare this product

Characteristics

- Type

- floor-standing

- Configuration

- centrifugal

- Material

- steel, composite

- Ecological characteristics

- energy-saving

Description

Howden, a leading global provider of mission-critical air and gas handling products, is pleased to promote the ExVelTM Composite turbo fan. The key to this revolutionary technology is the ExVel turbo fan impeller engineered and produced from carbon fiber composite, which is ideally suited for glass manufacturers. Howden has over 20 years of development and installation experience with these special carbon fiber composite designs applied to the unique aerodynamic structure of the ExVel impeller. Now glass manufacturers can realise improved plant safety, reliability and lifetime over traditional steel fan impellers.

First and foremost, we’re pleased to report plant safety is substantially improved through the composite impellers’ ability to combat fatigue. They are not susceptible to cyclic fatigue failure like impellers made from steel and other metals, which reduces the potential for unplanned downtime, and more importantly, catastrophic failures that can lead to equipment damage and bodily injuries.

Mark Sanders, President of the Americas Region at Howden

ExVel Composite turbo fans improve reliability with their nearly unlimited fatigue life. They also weigh substantially less than steel, consuming less energy and resulting in lower loads and wear to connected components like bearings and couplings. The higher reliability leads to less planned and unplanned downtime and reduced maintenance costs.

Plus, there’s no practical limits on speed changes. This allows manufacturers to utilise variable speed fan control, which is the most energy efficient method, and there’s no need for guide vanes. The ExVel Composite turbo fan is able to accelerate and decelerate in as fast

Catalogs

No catalogs are available for this product.

See all of Howden BC Compressors‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.