- Materials - Tools - Components

- Auto body shop equipment

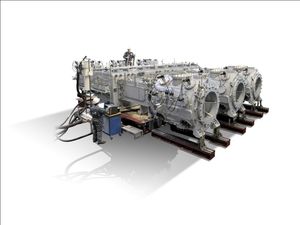

- Membrane compressor

- Howden BC Compressors

Membrane compressor airelectrically-poweredstationary

Add to favorites

Compare this product

Characteristics

- Technology

- membrane

- Type

- air

- Power source

- electrically-powered

- Portability

- stationary

- Lubrication

- lubricated

- Application domain

- industrial

- Other characteristics

- high-pressure

- Pressure

3,000 bar

(43,511.32 psi)- Power

250 kW

(339.91 hp)

Description

Burton Corblin® metal diaphragm compressors provide non-contaminating, leak-tight compression of any gas. They are especially suited to applications requiring complete gas isolation from the external environment. High compression ratio and high pressure capabilities have resulted in them being used for specialist applications in the chemical and industrial gases industries.

While looking for a chlorine compression system, Henri Corblin invented the metal diaphragm compressor in 1916. Its compressor heads fully confine the gas in a leak-tight compression chamber. Sealing is ensured by static contact and is monitored by our Head Integrity Detection System (HIDS). Since its inception we have manufactured more than 8000 diaphragm compressors ranging up to 3000bar (43,500psi) and 250kW.

Catalogs

No catalogs are available for this product.

See all of Howden BC Compressors‘s catalogsRelated Searches

- Compressor stage

- Air and dry gas compressor

- Positive-displacement compressor

- Fixed compressor

- Industrial compressor

- Electrically-powered compressor

- Reciprocating compressor

- Oil-injected compressor

- Dry compressor

- Screw compressor

- Gas compressor

- High-pressure compressor

- Compressor for chemical applications

- Diaphragm compressor

- Compressor for heavy-duty applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.