- Products

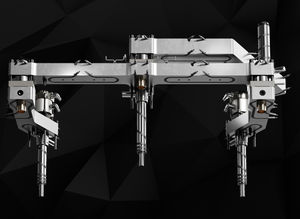

- Valve gate system

- HRSflow

Valve gate system

Add to favorites

Compare this product

Description

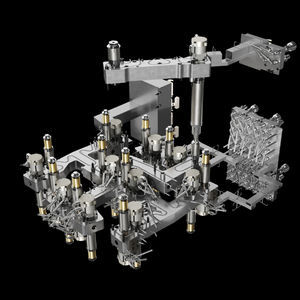

The special geometry of the hot runner minimizes pressure drops and optimizes color change

New single nozzle screwed into the base for single valve gate injection; also suitable for polymers where the molding cycle phase is reduced.

An Oerlikon HRSflow single nozzle system has the nozzle screwed directly into the tempered base to ensure the system has the required mechanical strength to deal with the thrust coming directly from the IMM barrel nozzle.

The nozzles – heated by coil heaters – are specially-designed to achieve optimal control of both internal and injection point temperature.

Internal duct geometry is specially designed to eliminate risk of material stagnation points and, as a result, favor color change and reduce the pressure drops in the system.

Advantages

Uniform temperature profile along the whole length of the nozzle

High mechanical strength of the base.

Specially designed geometry to minimize stagnation and pressure drops and optimize color change

Catalogs

No catalogs are available for this product.

See all of HRSflow‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.