- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Water cooler

- H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

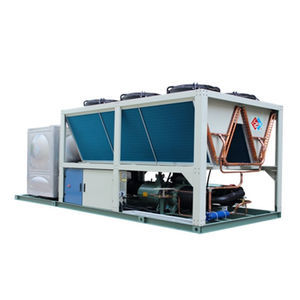

Water chiller 40STE seriesindustrialair-cooledpressure

Add to favorites

Compare this product

Characteristics

- Material

- water

- Applications

- industrial

- Other characteristics

- air-cooled, pressure, air-cooled, screw, shell and tube

- Power

Max.: 220.8 kW

Min.: 40.8 kW

- Maximum temperature

Max.: 55 °C

(131 °F)Min.: -35 °C

(-31 °F)- Flow rate

Max.: 241 m³/h

(8,510.835 ft³/h)Min.: 10.1 m³/h

(356.678 ft³/h)- Pressure

Max.: 0.66 bar

(9.572 psi)Min.: 0.28 bar

(4.061 psi)

Description

Industrial Manufacturing Glycol Ultra Low Temperature Recirculating Air Cooled Chiller

Low temperature chiller manufacturers -- H.Stars 40STE series screw type low temperature air-cooled chiller adopts high efficiency dual screw compressors, equipped with self-made high-efficiency shell and tube heat exchangers and fin type heat exchangers. Heat recovery unit can be configured based on customer needs,which is suitable in pharmaceutical, chemical, electronics, food processing, etc. The unit has 24 standard specifications, cooling capacity range: 60kw~340kw, chilled glycol outlet temperature: 5 °C ~ -35 ° C.

Customized Design

The industrial low temperature chiller can be designed according to the dimension of the machine room, and it can be delivered to the site by CKD (completely knock down ) or SKD(semi knock down) or the whole unit. Different power supply are available according to different countries and regions ,such as high-voltage non-standard chiller .

Heat Recovery Unit (optional)

Own a heat recovery patent.

Waste heat generated in the refrigeration process is recovered by H.Stars patented heat recovery unit to provide free hot water up to 55°C. Boiler replacement to save operating cost.

Professional Design

According to user's requirements, H.Stars provides professional advice and selects the most suitable equipment which fits perfectly for each project. Different materials of heat exchange will be recommended to avoid corrosion and leakage according to user’s refrigeration medium used in the project.

Energy-saving Design (optional)

The variable frequency drive technology greatly improves the Partial load energy efficiency of the chiller ;

Catalogs

No catalogs are available for this product.

See all of H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.‘s catalogsOther H.Stars (Guangzhou) Refrigerating Equipment Group Ltd. products

INDUSTRIAL CHILLER

Related Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Air chiller

- Liquid/liquid heat exchanger

- Industrial chiller

- Compact chiller

- Tubular heat exchanger

- Stainless steel chiller

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Blast chiller for the food industry

- Air-cooled recirculation chiller

- Industrial heat exchanger unit

- Oil chiller

- Laboratory recirculation chiller

- Compact heat exchanger unit

- Process water cooler

- Copper heat exchanger

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.