- Products

- Catalogs

- News & Trends

- Exhibitions

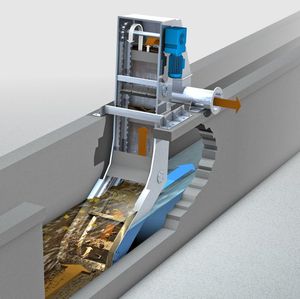

Sewage sludge screener ROTAMAT® Ro3screwdrumfor wastewater

Add to favorites

Compare this product

Characteristics

- Applications

- sewage sludge

- Type

- screw, drum

- Material

- for wastewater

- Other characteristics

- inclined

Description

Well-proven, efficient and rugged Septage Receiving Station

with integrated screenings press

with integrated screenings washing

no odour annoyance outside

This septage receiving station is used for mechanical treatment of septic sludge.

A HUBER Fine Screen ROTAMAT® Ro1 is installed in a tank. The septic sludge is fed into the tank and, as it flows through the Fine Screen, all coarse material is retained. A screw conveyor with integrated screenings press removes the screenings from the tank, reduces their volume and weight and drops them into a container or bagging device. The entire treatment takes place in a fully enclosed system; odour nuisance is thus prevented.

High separation capacity

Due to the diversion in the basket the fibrous materials and the bar-shaped particles are considerably better retained than the particles flowing straightly to the rack screen.

Low head loss

Due to the drum shape and the 35° installation considerably more screening area is available for the cleaning than for instance with screening systems installed vertical or inclined. The result: low head loss - maximum throughput

Completely made of stainless steel

The machine is completely made of stainless steel and acid-treated in a pickling bath which eliminates labour-intensive maintenance work otherwise caused by corrosion.

Automatic cleaning

By means of the circulating screening rake the complete screening area is totally cleaned, i.e. even at high pollution load the automatic cleaning ensures a constantly free screening area.

Catalogs

No catalogs are available for this product.

See all of Huber Technology‘s catalogsRelated Searches

- Screening unit

- Compact screening machine

- Inclined screening unit

- Drum screening unit

- Solid/liquid sieving machine

- Liquid sieving machine

- Rotary screening machine

- Self-cleaning screening unit

- Spiral screener

- Separator screen

- Dewatering screening unit

- Drainage screener

- Washer screening unit

- Perforated sheet metal sieving machine

- Wastewater screener

- Sewage sludge screener

- Sludge treatment separator screen

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.