- Machine-tools

- Cutting Tool

- Ball nose milling cutter

- Hufschmied Zerspanungssysteme GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

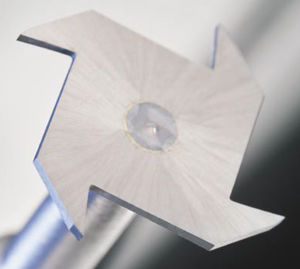

Ball nose milling cutter PROTO-LINE/HM905 seriessolid carbideslotfor plastics

Add to favorites

Compare this product

Characteristics

- Geometry

- ball nose

- Construction

- solid carbide

- Type

- slot

- Treated material

- for plastics

- Other characteristics

- miniature, HSC

- Diameter

Min.: 0.2 mm

(0.01 in)Max.: 2 mm

(0.08 in)- Length

Min.: 38 mm

(1.5 in)Max.: 75 mm

(2.95 in)

Description

Plastic materials are used more often in the mechanical engineering, constructions and also in the mould and die making industry. Therefore the needs to reach best quality in the part surface and accuracy are also increasing as the demands for higher tool life and faster working possibilities. This means that the time is right for PROTO-LINE tools.

Special cutting geometries and solid carbide materials are giving the possibility of highest tool lifes also with short cycle times in combination with smooth and burr free parts.

Expecially in the mould and die-making industry are even more UREOL materials used, which are adapted with different additives to the special needs of the job.

Due to the miniaturisation in the industry the Hufschmied Mini Mills starting with 0.2mm up to 3mm are special designed for the Mould and die making as well as in the prototyping industry.

Catalogs

No catalogs are available for this product.

See all of Hufschmied Zerspanungssysteme GmbH‘s catalogsOther Hufschmied Zerspanungssysteme GmbH products

PLASTIC-MACHINING

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Steel milling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- End mill milling tool

- Coated milling cutter

- General purpose drill bit

- Hemispherical milling cutter

- Solid carbide milling tool

- Carbide drilling tool

- Roughing milling tool

- Shell-end milling tool

- 2-flute milling tool

- Twist drilling tool

- Slot milling tool

- Hardened steel milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.