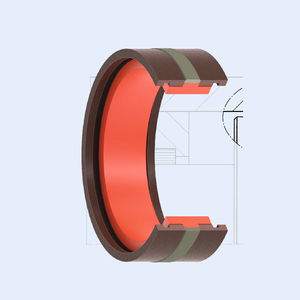

Lip seal TDA seriesC-ringpolyurethaneelastomer

Add to favorites

Compare this product

Characteristics

- Type

- lip

- Configuration

- C-ring

- Material

- polyurethane, elastomer, NBR, PTFE

- Application

- fitting, piston, for cylinders, oil, tube, wall, edge, parts, slide, cylinder, rod

- Fluid

- for water, air

- Temperature limit

Min.: -35 °C

(-31 °F)Max.: 100 °C

(212 °F)- Pressure limit

450 bar

(6,526.7 psi)- Outer diameter

70 mm

(2.756 in)- Shore A hardness

40 unit

- Speed

1 m/s

(3.3 ft/s)

Description

The HUNGER TDA tandem seal for outside sealing

is used to seal pistons, plungers and accumulators. It

can be applied with mineral oils and in modified form

also with water base fluids, fire resistant fluids and

compressed air.

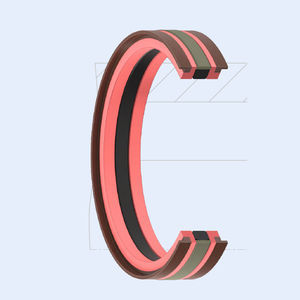

The TDA seal consists of 2 parts, an elastic ring of PUR

with a sealing lip and a slide ring of abrasion resistant

PTFE-Bronze-Compound with a sealing edge. Prior

to fitting, the sealing lip protrudes beyond the nominal

diameter of the seal and is pressed against the cylinder

wall after fitting. Thus effective sealing is provided even

at zero pressure.

The slide ring is surrounded by the elastomer sealing

ring and moves axially in direct contact with the inside

of the tube. With increasing pressure and compression

of the sealing ring, it is the slide ring which is predominantly

pressed against the inside of the cylinder.

The slide ring sealing edge produces an annular cavity

where any seepage oil that has passed the elastomer

lip is collected.

The seepage oil is held back by the sealing edge, such

that the emerging piston rod remains dry. During the

return stroke, the collected oil is forced back into the

cylinder.

The outer sealing surface of the TDA mainly comprises

the external slide ring which has excellent sliding

properties. When combined with a surface finish

Ra 0.1 - 0.3 μm of the cylinder tube, minimum friction

levels are achieved with highly efficient sealing and long

service life. There is no stiction, no unacceptable heat

generation and above all no stick-slip effect.

Catalogs

TDA

6 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.