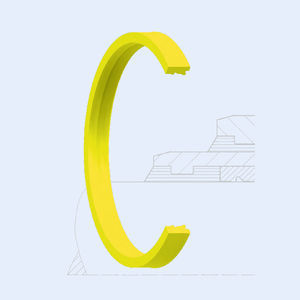

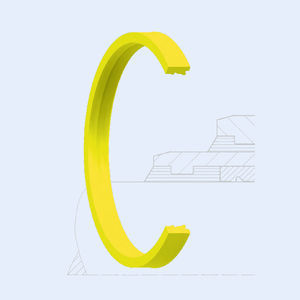

Lip seal TRO-I seriesPTFEPURcompression

Add to favorites

Compare this product

Characteristics

- Type

- lip

- Material

- PTFE, PUR

- Application

- compression, parts, slide, cylinder, rod

- Other characteristics

- dynamic, static

- Temperature limit

Min.: -35 °C

(-31 °F)Max.: 100 °C

(212 °F)- Pressure limit

450 bar

(6,526.7 psi)- Diameter

90 mm

(3.543 in)- Shore A hardness

40 unit

- Speed

1.5 m/s

(4.9 ft/s)

Description

Tandem Seal,

friction optimized, inside sealing

Single acting rod seal with improved performance in

regard of static and dynamic friction.

Influencing seal friction and and efficiency can be

approached by changing material composition or

implementing différent kinds of fillings as well as by

changing the design or geometrical shape of com-

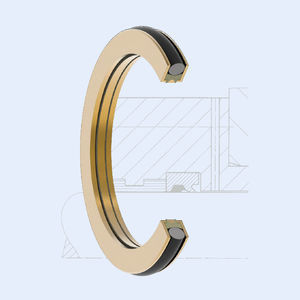

ponent parts. Components of PUR energizer and

PTFE-Compound slide ring have been completely

new designed and adjusted resulting in a new kind of

tandem rod seal called TRO-I.

Perfomance in regard of static and dynamic seal friction

was significantly improved with this smooth-running

further development.

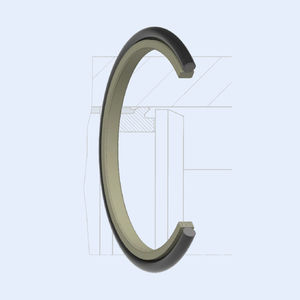

The new slide ring design almost extends over the

whole width of PUR-energizer and supports also the

back of seal which leads to low friction contact between

PTFE and cylinder rod under system pressure and

axial compression of the seal.

Pressure averted side of slide ring has a modified

step-seal shape for positive effect on the hydrodynamic

back pumping of dragged out fluid films and to avoid

a pressure build up between tandem arrangement of

seals.

Shape of slide ring also leads to an improved protec-

tion against gap extrusion under pressure loadings.

This new design reduces heat génération by friction

and allowes considerably higher movement speeds

of the system.

Adherence, sticking or stick-slip effects due to high

breakaway forces is avoided. TRO-I seal can be

combined in tandem arrangements as primary or

secondary seal - as well as redundant double set up

for applications where spécial requirements regarding

leak tightness is needed.

Catalogs

No catalogs are available for this product.

See all of Hunger‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.