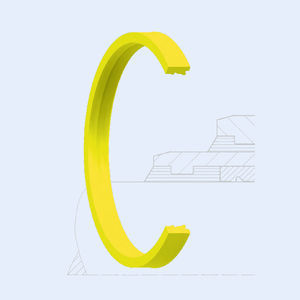

Lip seal TDT seriesPURfittingcompression

Add to favorites

Compare this product

Characteristics

- Type

- lip

- Material

- PUR

- Application

- fitting, compression, oil, construction, edge, cylinder

- Fluid

- air

- Other characteristics

- compact

- Temperature limit

Max.: 100 °C

(212 °F)Min.: -35 °C

(-31 °F)- Pressure limit

360 bar

(5,221.4 psi)- Diameter

Max.: 2,000 mm

(78.74 in)Min.: 39 mm

(1.535 in)- Outer diameter

42 mm

(1.654 in)- Shore A hardness

40 unit

- Speed

1 m/s

(3.3 ft/s)

Description

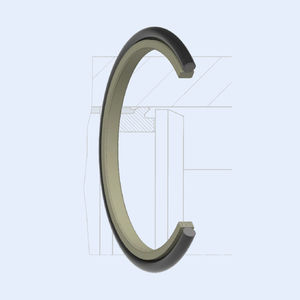

The HUNGER tandem seal type TDT is designed

for use with telescopic cylinders. It can be used with

mineral oils or compressed air.

The TDT seal is manufactured in PUR and has two

sealing lips on the inside. Prior to fitting, these lips

protrude beyond the nominal diameter of the seal.

Following installation, seal compression forces the

lips against the telescopic cylinder stages, thereby

providing a sealing function at zero pressure.

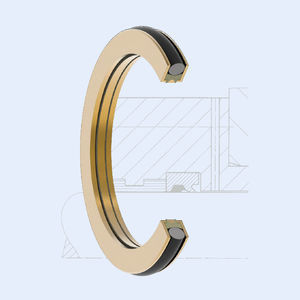

Under increasing pressure and compression of the seal,

the sealing lips are pressed against the telescopic cylinder

stages. The sealing edge of the second lip produces

an annular cavity, where any seepage oil that has passed

the first lip is collected. The seepage oil is held back

by the sealing edge such that the emerging telescopic

cylinder stages remain dry. During the return stroke, the

collected oil is forced back into the cylinder.

When combined with a surface finish of Ra 0.1 - 0.3

μm of the running surface, minimum friction levels are

achieved with highly efficient sealing and a long service

life. When used with the HUNGER FI type bearings, a simple

and compact construction is possible for all telescopic

cylinder stages.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.