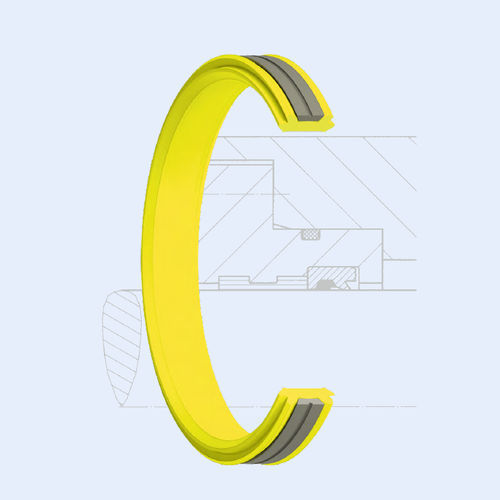

The HUNGER TDMA tandem seal for multi-fluid

outside sealing application is used to seal pistons

and plungers. It can be used with mineral oils and in

modified form with compressed air.

The TDMA seal consists of two parts, an elastic ring

of PUR with 2 sealing lips and a slide ring of abrasionresistant

PTFE-Bronze Compound with 2 sealing

edges. Prior to fitting, the sealing lips protrude beyond

the nominal diameter of the seal and are pressed

against the cylinder wall after fitting. Thus effective

sealing is provided even at zero pressure.

The slide ring is surrounded by the elastomer sealing

ring and moves axially in direct contact with the inside

of the tube. With increasing pressure and compression

of the elastic ring, it is the slide ring which is predominantly

pressed against the inside of the tube. The

outer sealing surface of the TDMA mainly comprises

the slide ring which has excellent sliding properties.

When combined with a surface finish Ra 0.1 - 0.3 μm

of the cylinder tube or the piston rod, minimum friction

levels are achieved with highly efficient sealing and

long service life.

There is no stiction, no unacceptable heat generation

and above all no stick-slip effect.

The TDMA seal is recommended for use where different

fluids on each side are to be separated.

It is also suitable for sealing grease chambers against

the ingress of water or other fluids.

Due to its good dry running properties, it can be used

as a fluid seal on one side and simultaneously as a

dirt wiper on the other side.