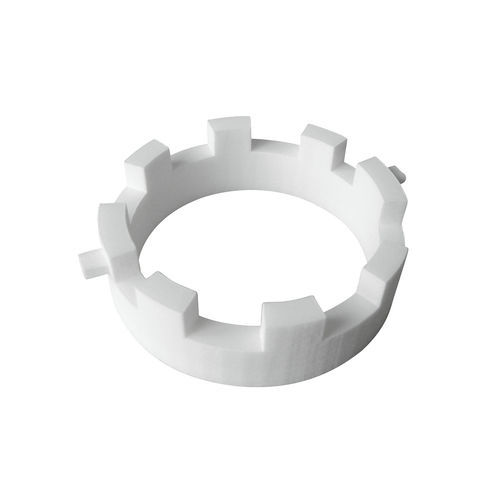

Laser sintering is a process which creates heavy-duty prototypes by melting on layers of a plastic powder. The thickness of the layers is about 0.1-0.2 mm.

At specific places in each layer of the component, a laser applies high energy to melt the material locally. The component is then sunk and the process begins from the beginning with the geometrical data of the next layer until the complete component is finally created.

Depending on the use of the later prototype, different materials can be processed, e.g. unfilled or filled polyamide. The models can have highly complex 3D structures and are distinguished by a high chemical and thermal resistance corresponding to the plastic PA 12.

Delivery time for laser sintered parts is usually around 4-5 days.

Heavy-duty prototypes

High chemical and thermal resistance (similar to PA 12)

Manufacturable unfilled and filled (glass fibre)