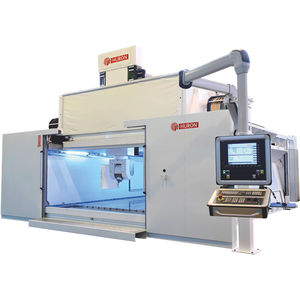

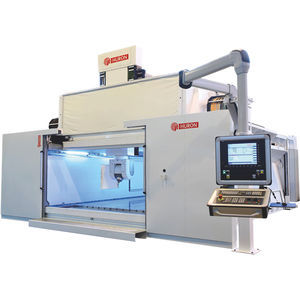

5-axis CNC milling center KX 50 Mverticalwith fixed portaldouble-column

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- with fixed portal, double-column, with fixed table

- Spindle mount

- HSK-63-A

- Number of tool stations

- 36 tools

- Applications

- for the aeronautical industry, for large workpieces

- Other characteristics

- high-performance, high-productivity

- X travel

2,000 mm

(78.74 in)- Y travel

1,700 mm

(66.93 in)- Z travel

900 mm

(35.43 in)- Rotational speed

20,000 rpm

(125,664 rad.min-1)- Power

75 kW

(101.97 hp)- Work feed X-axis

40,000 mm/min

(26 in/s)- Work feed Y-axis

40,000 mm/min

(26 in/s)- Work feed Z-axis

40,000 mm/min

(26 in/s)- Table load capacity

400 kg

(882 lb)- Tool weight (max)

8 kg

(17.6 lb)- Positioning accuracy

0.007 mm

(0.00028 in)- Repeatability

0.004 mm

(0.00016 in)- Weight

31,000 kg

(68,343.3 lb)- Overall width

6,630 mm

(261 in)- Overall height

5,140 mm

(202.4 in)

Description

The KX Large Series offers a wide selection of machines for continuous five-axis/five-side machining of complex parts.

The fixed-portal architecture and machine design ensure maximum rigidity for extremely precise machining in a variety of difficult materials.

Its large work area, capable of supporting up to 20 tonnes in weight and accomodating processable volumes up to 4.080 x 2.180 x 1.550 mm, is suited to machining large parts for general mechanical and precision engineering, 3D shapes, and the aeronautical and energy sectors.

Customer reguirements are comfortably met by the modularity of design, the choice of variants, and equipment.

Key Features

Volumetric precision for making moulds and complex parts

Wide clearance between the columns to exploit the work volume fully

Spindle offering optimum performance for roughing and finishing

Spindle suited to high chip rates

Structural design guaranteeing long mechanical life

High degree of precision due to direct measurement on the linear and rotary axes

Catalogs

No catalogs are available for this product.

See all of HURON‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- CNC turning center

- 3-axis CNC machining center

- 2-axis turning center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- 3-axis CNC milling machine

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- 12 tools turning center

- Milling CNC machining center

- High-productivity CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.