- Health - Safety - Environment

- Building Security and Machine Safety

- Hutchinson Precision Sealing Systems

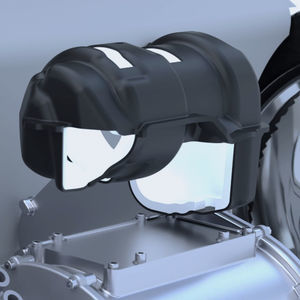

Gas holder seal 2509274

Add to favorites

Compare this product

Description

Our gasholder seals are compatible with Wiggins type dry gasholders, up to 100,000 m3, used in steel plants, but also for conical gasholder in biomass and chemical plants. Our gasholder seals are resistant to converter gas and BOF (Blast Open Furnace) that can be found in Wiggins gasholders.

To ensure the highest level of quality the process is fully integrated, from material development in our Hutchinson research and innovation centre, through rubber production, calendering, manufacturing and inspection to assembly supervision.

The design of the membrane and its hot vulcanized welds give the membrane a special flexibility and resistance, limiting constraints and areas of accelerated aging. This robustness enables an extended service life around 20 years, reduces maintenance interventions and the corresponding risks.

TECHNICAL FEATURES

TN300P Type

Application: Wiggins dry gasholder

Textile insert: Nylon cord fabric, bi-axial at 90°

Rubber Compound: Protected NBR

Gas Resistance: CO, CO2, methane, converter gas

Thickness: 3.25mm

Longevity: 2,000,000 flexions

Working temperature: -35°C to +80°C

Ozone resistance: no visible cracks

Qualifications: In-house test bench, inspection, and traceability of all hot vulcanized welds

BENEFITS

Longevity

Custom-design

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other Hutchinson Precision Sealing Systems products

Special solutions

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.