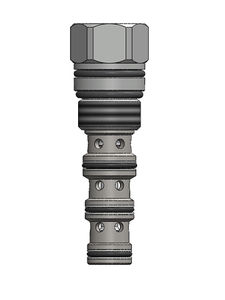

Poppet check valve HCV10-P1cartridgeGhigh-pressure

Add to favorites

Compare this product

Characteristics

- Type

- poppet, cartridge

- Connexion

- G

- Applications

- high-pressure

- Other characteristics

- spring, compact, standard, standard

- Pressure

420 bar

(6,091.6 psi)- Temperature

Min.: -54 °C

(-65 °F)Max.: 204 °C

(399 °F)- Flow rate

160 l/min

(42.27 us gal/min)

Description

HCV10-P1 allows flow from ① to ②, and blocks flow in the opposite direction.

The cartridge has a fully guided poppet which is spring-biased closed until sufficient is applied at pressure is applied at ①, allowing fluid flow from ① to ②.

Features

Fast and smooth response to pressure changes.

Positive stops prevent springs from going solid.

Compact size.

Adjustments cannot be backed out of the valve.

Industry common cavity.

Hardened poppet and cage for long life.

Flow: See performance chart

Internal leakage: 0.15 mL/min (3 drops/min) max. at 420 bar (6000 psi)

Crack(set) pressure defined: Gauge bar evident at ① at 16.4mL/min (1 cu. in. /min) attained.

Standard bias spring at crack: 0.3 bar (4 psi) / 1 bar (15 psi) / 2 bar (29 psi) / 4 bar (58 psi) / 5 bar (73 psi) / 10 bar (145 psi) / 20 bar(290 psi)

Fluid: Mineral based or synthetics with lubricating properties at viscosities of 7.4~420 cSt (50-2000 ssu)

Installation: No restriction

Cavity: V10-2

Cavity tool: T/H10-2RC-T-G (Rough), T/H10-2FM-T-G (Finishing)

Seat kit: SK10-2N -B

Catalogs

No catalogs are available for this product.

See all of Hydrabase‘s catalogsRelated Searches

- Valve

- Control valve

- Threaded valve

- Electrically operated valve

- Stop valve

- Flap valve

- Non-return valve

- Directional control valve

- Normally closed solenoid valve

- 2-way solenoid valve

- Direct-operated solenoid valve

- Hydraulic valve

- Compact valve

- Hydraulic directional control valve

- Fluid check valve

- Flow control valve

- IP65 solenoid valve

- Spool hydraulic directional control valve

- Relief valve

- 3-way solenoid valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.