Condensate filter cartridge DairyRO-3838-30waterdesalinationpolyamide

Add to favorites

Compare this product

Characteristics

- Media

- water, condensate

- Type of filtration

- desalination

- Material

- polyamide

- Applications

- for general purposes, for reverse osmosis, high-pressure, high-temperature

- Domain

- industrial, automatic

- Other characteristics

- membrane, membrane, high-temperature, high-pressure

Description

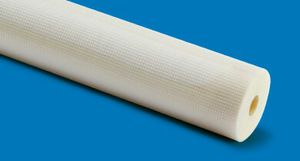

Hydranautics’ 40+ years of manufacturing best high rejecting brackish water RO membranes is incorporated into making DairyRO and HYDRApolish elements.

DairyRO and HYDRApolish composite polyamide reverse osmosis elements are of net wrapped, full fit design, intended for daily CIP in the dairy environment. Hydranautics has set new industry standard by manufacturing robot-based automatic rolling machines, specially designed for fabricating membrane modules of the highest quality. The result is a high level of filtration and separations performance for our customers. Hydranautics’ auto-rolled DairyRO and HYDRApolish elements provide superior glue-line adhesion and strength, tighter rolling and caging, greater flow rates due to maximized effective membrane area and great structural reliability.

HYDRApolish is designed specifically for dairy process applications requiring continuous operation at high pressure, high temperature, or periodic heat sanitization at high temperature.

All DairyRO and HYDRApolish products are USDA accepted. Components conform to FDA regulation CFR Title 21, “3A Sanitary Standards for Crossflow Membrane Modules, Number 45-02”, EC Reg. No. 1935/2004, and EU Reg. No. 10/2011.

DairyRO applications

Pre-concentration of milk or whey for reducing product transport costs

Lactose Production

Sweet/acid concentration

Concentration of UF permeate

Milk and juice concentration

HYDRApolish applications

RO permeate polishing

Condensate polishing

Pre-concentration of milk or whey for reducing product transport costs

Lactose Production

Juice concentration

Catalogs

DairyRO®

2 Pages

Related Searches

- Liquid separator filter

- Filter cartridge

- Industrial filter cartridge

- Filter for industrial applications

- Fine filter cartridge

- Water separator filter

- General purpose filter cartridge

- Water filter cartridge

- Polymer filter cartridge

- Chemical product filter cartridge

- Membrane filter cartridge

- PP filter cartridge

- Chemical filter cartridge

- Metal filter cartridge

- Capsule filter

- Depth filter cartridge

- Membrane filter

- Oil filter cartridge

- Foodstuff filter cartridge

- Pharmaceutical filter cartridge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.